Product Overview

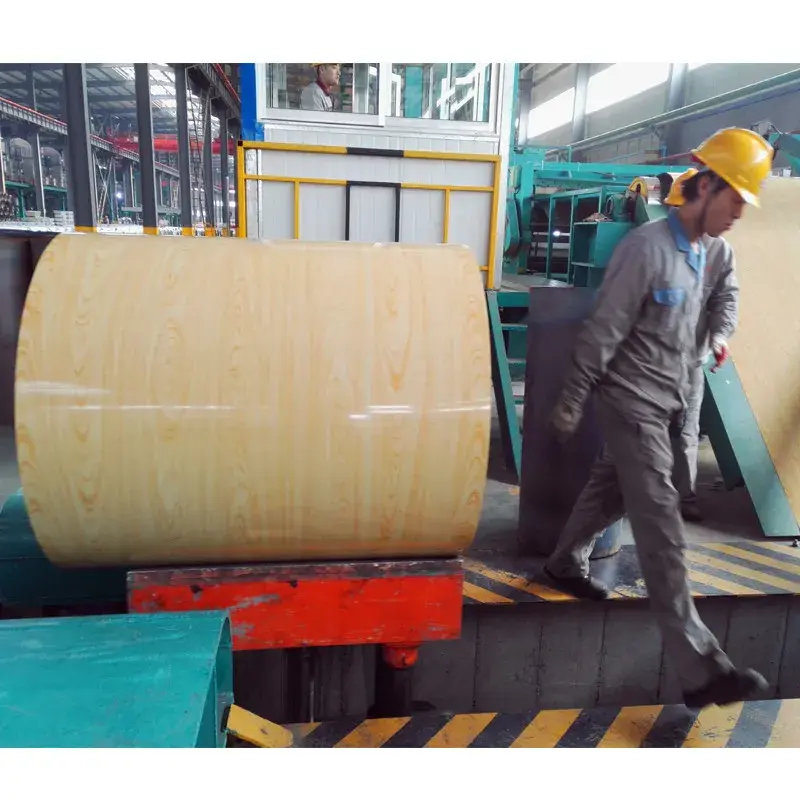

- The continuous color coating line product from HiTo is a result of advanced industrial technology, ensuring optimum quality and durability.

- HiTo offers tailored solutions to meet individual requirements, production goals, and budgets, providing a competitive advantage to customers.

- The color coating unit adopts a double-coating double-baking model and hot air circulation heating process, suitable for various base plate materials.

Product Features

- Suitable base plate materials include electro-galvanized plate, hot-dip galvanized plate, hot-dip Al-Zn plate, cold-rolled steel plate, and aluminum coils.

- The process speed ranges from 30 to 200m/min, with a production capacity of 30,000 to 300,000 tonnes/year.

- Additional services offered include project feasibility, equipment design, installation and commissioning, technology transfer, training, product testing, and ongoing technical support.

Product Value

- The HiTo color coating line offers the world's best technology at competitive pricing, backed by full specialist support.

- The product provides high precision in thickness control, allowing for various configurations and customization options.

Product Advantages

- HiTo's continuous color coating line is designed to meet the highest quality standards, providing superior performance and efficiency.

- The use of advanced technology and innovative engineering ensures a reliable and durable product.

- The ability to offer tailored solutions and provide ongoing support sets HiTo's product apart in the market.

Application Scenarios

- This product is suitable for industries requiring color-coated steel materials, such as construction, automotive, and home appliance manufacturing.

- The flexibility and precision of the color coating line make it ideal for producing pattern color-coated steel with various designs, including mood grain, marble, and brick patterns.