Latest Colour Coating Line Process Price List

Product Overview

- HiTo colour coating line process is manufactured using lean production practices and high-quality materials sourced internationally.

- The product quality is ensured through strict testing by a professional QC team, and it is produced using high-tech equipment.

Product Features

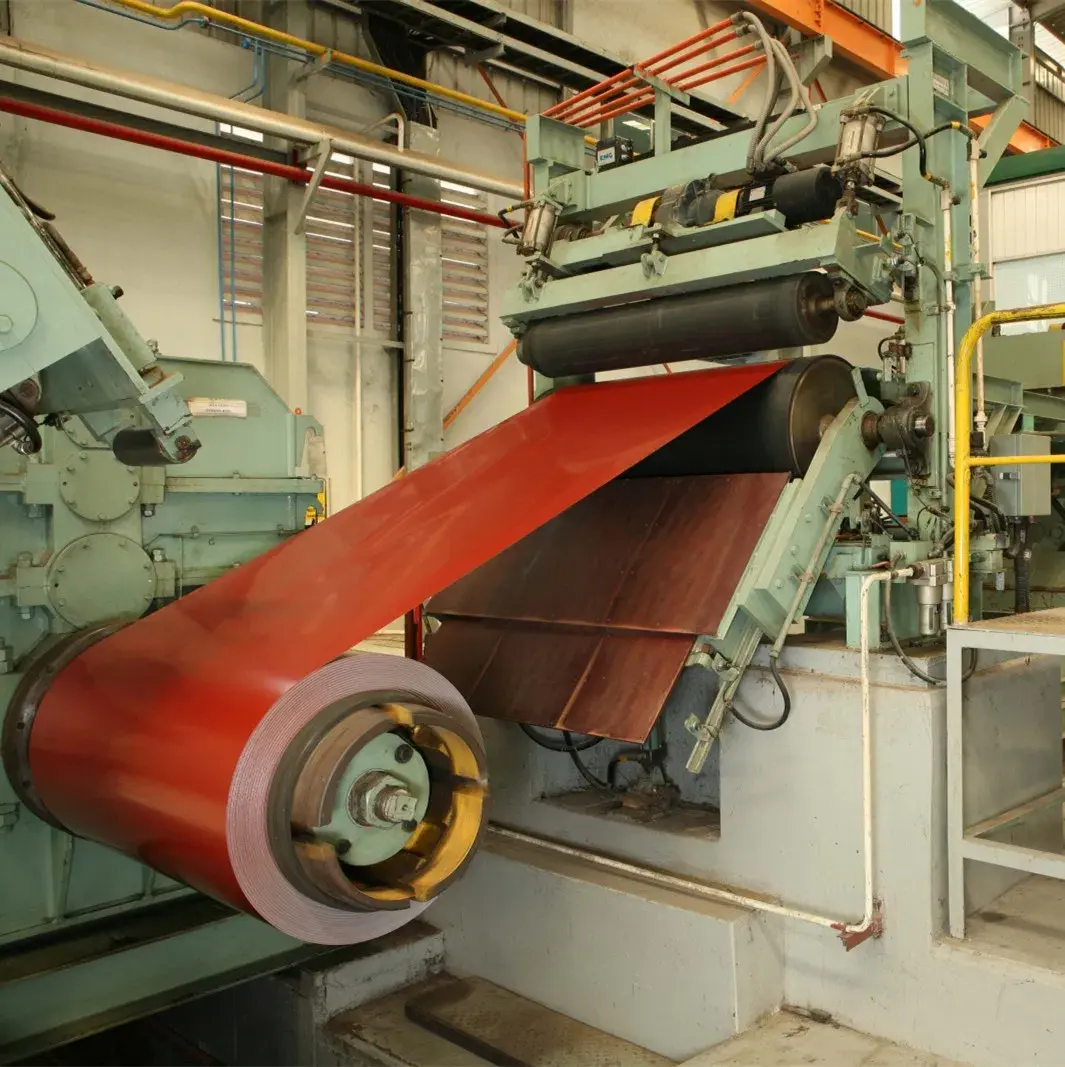

- The color coating unit adopts a double-coating double-baking model and hot air circulation heating process.

- Materials such as electro-galvanized plate, hot-dip galvanized plate, and cold-rolled steel plate can be used.

- The process speed ranges from 30 to 200m/min, with a production capacity of 30,000-300,000 Tonnes/year.

Product Value

- HiTo Equipment Engineering Co., Ltd focuses on innovation to provide customers with a competitive advantage.

- The company offers tailor-made solutions that align with individual preferences, production goals, and budgets.

- HiTo provides project feasibility, equipment design, installation and commissioning, technology transfer, training, product testing, downstream equipment, and ongoing technical support.

Product Advantages

- HiTo offers world-class technology at competitive pricing backed by full and ongoing specialist support.

- The company provides Pattern Printing System for producing pattern color-coated steel like mood grain and marble/brick pattern.

- The product meets general precision and high precision standards for thickness deviations based on different thickness ranges.

Application Scenarios

- The product can be used in various industries that require color coating processes for materials such as steel, aluminum, and other metals.

- Potential customers include manufacturing companies, construction firms, and industrial facilities looking to enhance their products with color coating technology.

- HiTo's color coating line process can be applied in the production of a wide range of products, including building materials, appliances, and automotive components.