The Ultimate Guide To Aluminum Composite Panel Production Line Setup And Operation

Are you looking to start or optimize your aluminum composite panel production line? Look no further! Our comprehensive guide covers everything you need to know about setting up and operating an efficient production line. From equipment selection to maintenance tips, we've got you covered. Don't miss out on this valuable resource for maximizing your production capabilities.

- Introduction to Aluminum Composite Panels

to Aluminum Composite Panels

Aluminum composite panels (ACP) are a popular building material used for both interior and exterior applications due to their durability, lightweight nature, and versatility. They are made up of two aluminum sheets bonded to a core material, typically a non-aluminum core such as polyethylene or mineral filled core. These panels are commonly used in the construction industry for facades, cladding, and signage.

The production of aluminum composite panels involves a complex process that requires specialized equipment and skilled labor. One of the key components in the production of ACP is the aluminum composite panel production line. In this article, we will provide an in-depth introduction to the aluminum composite panel production line, including its setup and operation.

Setup of Aluminum Composite Panel Production Line:

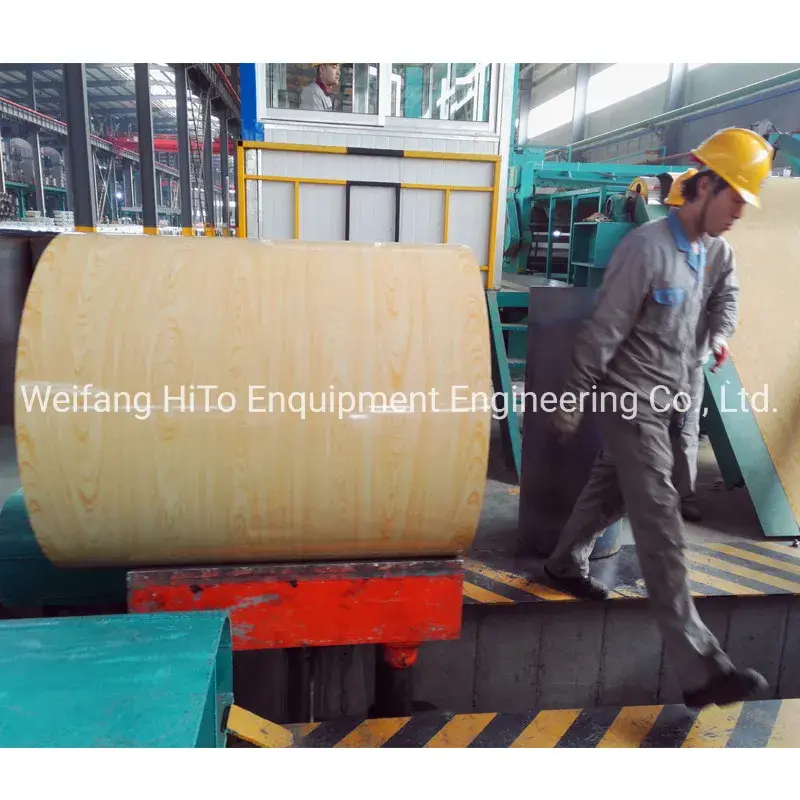

The setup of an aluminum composite panel production line starts with the selection of high-quality raw materials. The aluminum sheets used in ACP production must meet certain specifications in terms of thickness, coating, and alloy composition. The core material, whether it is polyethylene or another material, must also meet the required standards for strength, fire resistance, and durability.

Once the raw materials have been selected, they are fed into the aluminum composite panel production line. This production line typically consists of several key components, including a coating machine, a compounding machine, a hot press, and a cutting machine. Each of these machines plays a crucial role in the production process, from applying coatings to the aluminum sheets to bonding the sheets to the core material and cutting the finished panels to size.

Operation of Aluminum Composite Panel Production Line:

The operation of an aluminum composite panel production line requires skilled technicians who are familiar with the various processes involved in ACP production. The first step in the operation of the production line is the loading of the raw materials into the appropriate machines. The aluminum sheets are coated with a protective layer before being fed into the compounding machine, where they are bonded to the core material.

Once the panels have been compounded, they are fed into the hot press, where they are subjected to heat and pressure to ensure a strong bond between the aluminum sheets and the core material. After the panels have been pressed, they are cut to size using the cutting machine. This process requires precision and accuracy to ensure that the finished panels meet the required specifications.

In conclusion, the production of aluminum composite panels is a complex process that requires specialized equipment and skilled labor. The aluminum composite panel production line plays a vital role in this process, from the setup of the production line to the operation of the various machines involved. By understanding the key components and processes of the aluminum composite panel production line, manufacturers can ensure the production of high-quality ACP that meets the industry standards.

- Understanding the Production Line Setup Process

When it comes to setting up and operating an aluminum composite panel production line, understanding the production line setup process is crucial. The production line setup process plays a fundamental role in determining the efficiency and productivity of the operation. In this ultimate guide, we will delve into the intricacies of setting up and running an aluminum composite panel production line.

First and foremost, it is essential to understand the components of an aluminum composite panel production line. The production line typically consists of several key elements, including a coil handling system, a decoiler, a cleaning and pretreatment section, a coating machine, a drying oven, a roll coater, a laminating machine, a cutting machine, and a stacking and packing system. Each of these components plays a specific role in the production process, and they must be properly configured and integrated to ensure smooth operation.

The production line setup process begins with the installation of the various components in the correct order. The coil handling system is responsible for feeding aluminum coils into the production line, while the decoiler unwinds and feeds the coils into the cleaning and pretreatment section. This section removes any dirt, oil, or other contaminants from the surface of the aluminum coils to ensure proper adhesion of the coating.

Once the coils are cleaned and pretreated, they are fed into the coating machine, where a protective coating is applied to the surface of the aluminum. The coated coils then pass through a drying oven to cure the coating before moving on to the roll coater, where a layer of core material is applied. The coated coils are then fed into the laminating machine, where a layer of protective film is applied to the surface.

After the aluminum composite panels are laminated, they are cut to size using a cutting machine before being stacked and packed for shipping. Proper stacking and packing are essential to prevent damage to the panels during transportation and handling.

In addition to the physical components of the production line, it is also important to consider the operational aspects of setting up and running an aluminum composite panel production line. This includes training the operators on how to properly use and maintain the equipment, implementing quality control processes to ensure that the panels meet industry standards, and developing a production schedule to optimize workflow and minimize downtime.

Overall, understanding the production line setup process is essential for the successful operation of an aluminum composite panel production line. By carefully configuring and integrating the various components, training operators, and implementing quality control processes, manufacturers can ensure efficient and productive production of high-quality aluminum composite panels.

- Important Factors to Consider for Operating the Production Line

When setting up and operating an aluminum composite panel production line, there are several important factors that must be considered in order to ensure efficiency, quality, and safety. These factors play a crucial role in the success of the operation and should be carefully taken into account by those involved in the setup and management of the production line.

One of the key factors to consider when operating an aluminum composite panel production line is the quality of the raw materials used in the manufacturing process. It is essential to source high-quality aluminum and composite materials that meet industry standards and specifications. Using subpar materials can result in faulty panels that do not meet quality standards, leading to dissatisfied customers and wasted resources. Therefore, it is important to thoroughly vet suppliers and ensure that all materials meet the necessary criteria before beginning production.

Another important factor to consider is the maintenance and upkeep of the production line equipment. Regular maintenance is essential to prevent breakdowns and ensure the efficient operation of the machinery. This includes routine inspections, cleaning, and lubrication of equipment, as well as the replacement of worn-out parts. Neglecting maintenance can result in costly downtime and delays in production, so it is important to establish a regular maintenance schedule and adhere to it diligently.

Additionally, proper training of staff is crucial for the successful operation of an aluminum composite panel production line. Operators should be well-trained in the use of machinery, safety protocols, and quality control measures to ensure that panels are produced efficiently and meet the necessary standards. Investing in training programs and ongoing education for staff can help improve productivity and minimize errors in the production process.

Furthermore, safety is a critical factor to consider when operating a production line. Aluminum composite panel production involves the use of heavy machinery and equipment, which can pose risks to workers if proper safety measures are not in place. It is important to implement safety protocols, provide protective gear, and conduct regular safety training sessions to prevent accidents and ensure the well-being of all employees.

In conclusion, operating an aluminum composite panel production line requires careful consideration of several important factors, including the quality of materials, maintenance of equipment, training of staff, and prioritizing safety. By paying attention to these key factors, manufacturers can ensure the smooth and efficient operation of their production line, leading to high-quality panels and satisfied customers.

- Troubleshooting Common Issues in Aluminum Composite Panel Production

Aluminum composite panels (ACP) have become a popular choice in the construction industry due to their durability, versatility, and aesthetic appeal. In order to meet the growing demand for ACP, manufacturers are constantly looking for ways to improve their production processes. Setting up and operating an aluminum composite panel production line requires careful planning and attention to detail. However, despite following all the necessary steps, issues may still arise during the production process. In this article, we will explore some common problems faced by manufacturers during ACP production and provide troubleshooting tips to help resolve them.

One of the most common issues encountered in aluminum composite panel production is delamination. Delamination occurs when the layers of the panel separate from each other, compromising the structural integrity of the ACP. This can be caused by a variety of factors, such as improper adhesive application, inadequate curing time, or the use of low-quality materials. To prevent delamination, manufacturers should ensure that the adhesive is applied evenly and at the correct temperature, and that the panels are properly cured before further processing.

Another common problem in ACP production is bubbling or blistering on the surface of the panel. This can be caused by excessive moisture in the adhesive, uneven pressure during lamination, or improper mixing of the adhesive components. To avoid bubbling, manufacturers should store adhesives in a dry environment, use a roller or press to apply even pressure during lamination, and follow the manufacturer's instructions for mixing the adhesive components.

Mismatched colors or inconsistent finishes are also frequent issues in ACP production. This can be due to variations in material composition, improper coating application, or inadequate quality control measures. To ensure uniformity in color and finish, manufacturers should carefully select materials from the same batch, use a consistent coating application technique, and implement strict quality control checks throughout the production process.

In addition to these common issues, manufacturers may also encounter problems with panel flatness, panel cutting accuracy, or overall equipment malfunction. To address these issues, it is important to regularly maintain and calibrate the production line equipment, train operators on proper operation techniques, and conduct regular quality inspections to identify and resolve any issues quickly.

By understanding the common issues faced in aluminum composite panel production and implementing effective troubleshooting strategies, manufacturers can improve the quality and efficiency of their production processes. With proper planning, attention to detail, and a commitment to continuous improvement, manufacturers can successfully set up and operate an aluminum composite panel production line that meets the demands of the industry and delivers high-quality products to customers.

- Ensuring Safety and Efficiency in Operation of the Production Line

When setting up and operating an aluminum composite panel production line, ensuring safety and efficiency is paramount. With the right procedures in place, production can run smoothly, maintaining high quality standards and meeting demand.

First and foremost, safety measures must be a top priority in the setup and operation of the production line. This includes providing proper training for all personnel involved in the process, as well as implementing safety protocols and equipment to prevent accidents. Personal protective gear should be readily available and worn at all times to minimize the risk of injury.

In addition to safety, efficiency is key to success in aluminum composite panel production. By optimizing the layout of the production line and streamlining processes, companies can increase productivity and reduce downtime. Utilizing automated systems and advanced technology can also improve efficiency, allowing for faster production speeds without sacrificing quality.

Another important aspect of ensuring safety and efficiency in the operation of the production line is regular maintenance and upkeep of equipment. Routine inspections and servicing of machinery can help prevent breakdowns and ensure that production runs smoothly. It is also important to address any issues promptly to avoid costly delays in the production process.

Proper monitoring and quality control measures are essential in the production of aluminum composite panels. By implementing strict quality checks at each stage of the production line, companies can ensure that panels meet industry standards and customer expectations. This includes testing for durability, strength, and aesthetic appeal to guarantee a high-quality end product.

Moreover, environmental sustainability should be a consideration in the operation of the production line. Implementing eco-friendly practices, such as recycling materials and reducing waste, can help minimize the impact of production on the environment. Companies can also explore alternative energy sources to power their operations, further reducing their carbon footprint.

In conclusion, setting up and operating an aluminum composite panel production line requires a comprehensive approach to ensure safety and efficiency. By prioritizing safety measures, optimizing processes, maintaining equipment, monitoring quality, and promoting sustainability, companies can successfully run a productive and responsible production line. By following these guidelines, companies can streamline their operations, minimize risks, and produce high-quality aluminum composite panels for a variety of applications.

نتیجہ

In conclusion, setting up and operating an aluminum composite panel production line requires careful planning, attention to detail, and a thorough understanding of the process. By following the ultimate guide provided in this article and utilizing the right equipment and techniques, manufacturers can streamline their production process, increase efficiency, and ultimately produce high-quality aluminum composite panels. With the right knowledge and resources, any company can successfully set up and operate their own aluminum composite panel production line. By investing in the right tools and technology, manufacturers can stay ahead of the competition and meet the growing demand for this versatile building material.