The Ultimate Guide To Steel Coil Galvanizing Lines: Benefits, Process, And Applications

Are you looking to learn more about steel coil galvanizing lines and how they can benefit your business? Look no further than our comprehensive guide that covers everything from the process of galvanizing steel coils to the wide range of applications for this versatile technology. Whether you are new to the industry or an experienced professional, this ultimate guide will provide you with the knowledge you need to make informed decisions about incorporating steel coil galvanizing lines into your operations.

- Introduction to Steel Coil Galvanizing Lines

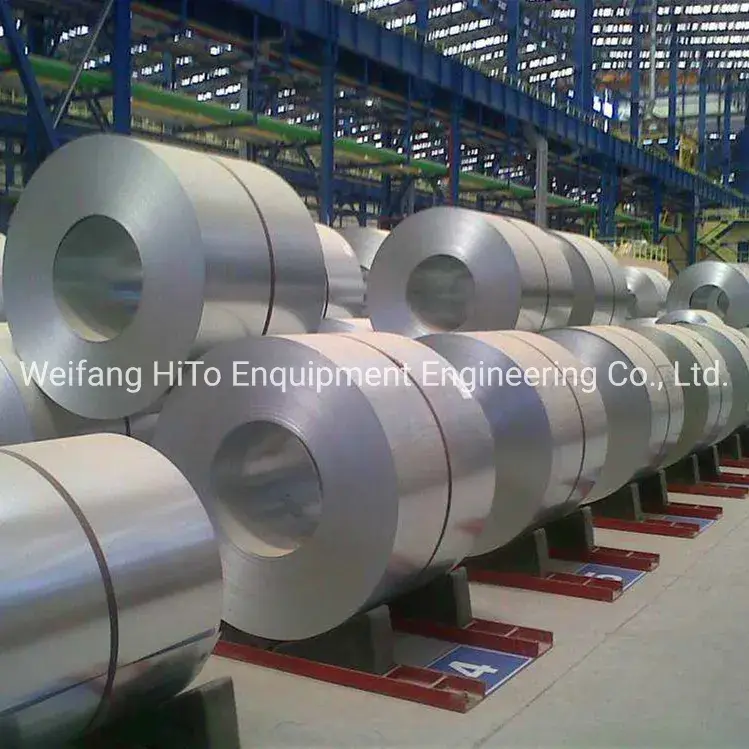

Steel coil galvanizing lines are essential equipment in the steel industry, playing a crucial role in the production of galvanized steel coils. In this comprehensive guide, we will delve into the benefits, processes, and applications of steel coil galvanizing lines.

to Steel Coil Galvanizing Lines:

Steel coil galvanizing lines are sophisticated machinery used to apply a protective zinc coating to steel coils, ensuring their longevity and resistance to corrosion. This process involves feeding the steel coils through a series of baths containing molten zinc, which adheres to the surface of the steel through a chemical reaction. The coated steel coils are then cooled, processed, and ultimately ready for use in various applications.

Benefits of Steel Coil Galvanizing Lines:

There are numerous benefits to using steel coil galvanizing lines in the steel industry. One of the main advantages is the superior corrosion protection provided by the zinc coating, which extends the lifespan of the steel coils and reduces maintenance costs. Additionally, galvanized steel coils have a high aesthetic appeal, making them ideal for architectural and construction purposes. Furthermore, the zinc coating also enhances the mechanical properties of the steel, increasing its strength and durability.

Process of Steel Coil Galvanizing Lines:

The process of galvanizing steel coils involves several steps to ensure a high-quality coating. First, the steel coils are cleaned to remove any impurities or surface contaminants. Next, the coils are annealed to improve their ductility and prepare them for the galvanizing process. The steel coils are then dipped into a series of zinc baths, where the molten zinc adheres to the surface of the steel. Finally, the coated steel coils are cooled, processed, and inspected for quality control before being shipped to customers.

Applications of Galvanized Steel Coils:

Galvanized steel coils produced by steel coil galvanizing lines are widely used in various industries due to their durability, strength, and corrosion resistance. One of the primary applications of galvanized steel coils is in the construction industry, where they are used to make roofing, siding, and structural components. Additionally, galvanized steel coils are also used in automotive manufacturing, appliances, and agricultural equipment. The versatility and reliability of galvanized steel coils make them a popular choice for a wide range of applications.

Steel coil galvanizing lines are an essential tool in the steel industry, providing numerous benefits and applications for galvanized steel coils. By understanding the process and advantages of using steel coil galvanizing lines, manufacturers can produce high-quality galvanized steel coils that meet the demanding requirements of various industries.

- Understanding the Process of Galvanizing Steel Coils

Steel coil galvanizing lines are an essential component of the steel industry, playing a crucial role in the production of galvanized steel coils. These lines are used to apply a protective zinc coating to steel coils, providing corrosion resistance and enhancing the overall durability of the material. In this article, we will delve into the process of galvanizing steel coils, exploring the benefits, applications, and key considerations of steel coil galvanizing lines.

The process of galvanizing steel coils begins with the preparation of the material. The steel coils are first cleaned and pickled to remove any surface impurities and oxides. This is essential to ensure proper adhesion of the zinc coating to the steel surface. Once the cleaning process is complete, the steel coils are then immersed in a bath of molten zinc, where the coating is applied through a process known as hot-dip galvanizing.

Hot-dip galvanizing is the most common method of applying zinc coatings to steel coils. In this process, the steel coils are passed through a series of tanks containing molten zinc, where the coating adheres to the surface of the steel. The coated coils are then cooled and inspected to ensure uniform coverage and adhesion of the zinc coating.

The benefits of galvanizing steel coils are numerous. One of the primary advantages is the enhanced corrosion resistance provided by the zinc coating. Galvanized steel coils are highly resistant to rust and corrosion, making them ideal for use in outdoor and humid environments. Additionally, the zinc coating acts as a sacrificial anode, providing an additional layer of protection to the steel substrate.

Steel coil galvanizing lines are used in a wide range of industries and applications. Galvanized steel coils are commonly used in the construction, automotive, and manufacturing sectors, where durability and corrosion resistance are essential. These coils are also used in the production of roofing materials, electrical enclosures, and agricultural equipment.

When considering a steel coil galvanizing line, there are several key factors to take into account. The capacity of the line, the size and weight of the coils it can accommodate, and the speed of the coating process are all important considerations. Additionally, the quality of the zinc coating, including its thickness and adhesion to the steel substrate, should be carefully monitored to ensure optimal performance of the galvanized steel coils.

In conclusion, steel coil galvanizing lines play a vital role in the production of galvanized steel coils, providing enhanced corrosion resistance and durability to the material. By understanding the process of galvanizing steel coils and the key benefits and applications of this technology, manufacturers can make informed decisions when investing in steel coil galvanizing lines.

- Benefits of Using Steel Coil Galvanizing Lines

Steel coil galvanizing lines are an essential component in the steel manufacturing industry, providing a myriad of benefits to companies that utilize them. From enhancing the durability and longevity of steel products to improving their aesthetic appeal, these lines play a crucial role in the production process.

One of the main advantages of using steel coil galvanizing lines is the enhanced corrosion resistance they provide. By coating steel coils with a layer of zinc, the risk of rust and deterioration is significantly reduced. This is especially important for industries that rely on steel products for outdoor applications or in harsh environments where exposure to moisture and corrosive elements is common.

Additionally, steel coil galvanizing lines help to improve the overall durability of steel products. The zinc coating acts as a protective barrier, shielding the underlying steel from damage caused by abrasion, impact, and other forms of wear and tear. This results in a longer lifespan for the products, saving companies money on replacements and repairs in the long run.

Another benefit of using steel coil galvanizing lines is the improved aesthetic appeal of the finished products. The shiny, metallic appearance of galvanized steel is visually appealing and can enhance the look of various consumer goods, building materials, and industrial components. This makes galvanized steel a popular choice for a wide range of applications, from construction to automotive manufacturing.

In addition to these benefits, steel coil galvanizing lines also offer environmental advantages. The zinc coating used in the galvanizing process is a recyclable material, making it a sustainable option for companies looking to reduce their carbon footprint. Furthermore, the increased durability of galvanized steel products means that they need to be replaced less frequently, leading to less waste and lower overall environmental impact.

Overall, steel coil galvanizing lines offer a multitude of benefits to companies in the steel manufacturing industry. From improved corrosion resistance and durability to enhanced aesthetic appeal and environmental sustainability, these lines play a crucial role in the production of high-quality steel products. By investing in steel coil galvanizing lines, companies can ensure that their products meet the highest standards of quality and performance, setting them apart from the competition in the global marketplace.

- Applications of Galvanized Steel Coils in Various Industries

Galvanized steel coils are a versatile material that finds applications in various industries due to its durability and resistance to corrosion. Steel coil galvanizing lines are crucial in the production process of galvanized steel coils, providing several benefits and ensuring high-quality finished products.

The steel coil galvanizing line is a complex machinery system designed to coat steel coils with a layer of zinc, which acts as a protective barrier against rust and corrosion. The process begins with the cleaning and pre-treatment of the steel coils to remove any impurities or contaminants. The coils are then immersed in a bath of molten zinc at high temperatures, ensuring a uniform and durable coating.

One of the main benefits of using a steel coil galvanizing line is the enhanced corrosion resistance of the finished product. Galvanized steel coils are widely used in the construction industry for roofing, siding, and structural components due to their ability to withstand harsh weather conditions and prolonged exposure to moisture. The zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and corrosion, thus extending the lifespan of the material.

In addition to its corrosion resistance, galvanized steel coils are also known for their high strength and reliability. The steel coil galvanizing line ensures consistent and uniform coating thickness, resulting in a durable and long-lasting product that can withstand heavy loads and harsh environments. This makes galvanized steel coils ideal for applications in the automotive, transportation, and manufacturing industries where strength and durability are essential requirements.

Furthermore, the aesthetic appeal of galvanized steel coils makes them a popular choice for architectural and decorative applications. The shiny and reflective surface of the zinc coating adds a modern and sleek look to buildings, appliances, and household items. The steel coil galvanizing line allows for customization of the coating thickness and appearance, making it suitable for a wide range of design options and finishes.

Overall, the applications of galvanized steel coils are vast and diverse, thanks to the benefits provided by steel coil galvanizing lines. From construction and manufacturing to automotive and interior design, galvanized steel coils offer a cost-effective and sustainable solution for various industries. With their superior corrosion resistance, strength, and aesthetic appeal, galvanized steel coils are a versatile material that continues to play a crucial role in modern industrial processes.

- Conclusion: The Importance of Steel Coil Galvanizing Lines

Steel coil galvanizing lines are essential in the steel industry for extending the lifespan of steel products and increasing their resistance to corrosion. In this concluding section, we will discuss the importance of steel coil galvanizing lines and how they contribute to the overall efficiency and effectiveness of the steel production process.

One of the key benefits of steel coil galvanizing lines is their ability to provide a protective coating to steel products. The process of galvanizing involves applying a layer of zinc to the surface of the steel, which acts as a barrier against moisture and other corrosive elements. This helps to prevent rust and corrosion, ultimately prolonging the lifespan of the steel products.

Furthermore, steel coil galvanizing lines also enhance the aesthetic appeal of steel products. The shiny, metallic finish created by the galvanizing process gives steel products a sleek and professional look, making them more attractive to consumers. This not only boosts the overall marketability of the products but also adds value to them in the eyes of customers.

In addition to these benefits, steel coil galvanizing lines are also crucial for maintaining the structural integrity of steel products. The protective zinc coating helps to strengthen the steel, making it more durable and resilient to wear and tear. This is especially important for products that are exposed to harsh environmental conditions or heavy usage, as the galvanizing process helps to prevent damage and maintain the structural integrity of the steel.

Another key aspect of steel coil galvanizing lines is their contribution to sustainability and environmental conservation. The galvanizing process is a highly efficient and environmentally friendly method of protecting steel products, as it requires minimal energy and resources to apply the zinc coating. This makes galvanized steel a more sustainable choice for construction and manufacturing applications, as it helps to reduce waste and minimize the impact on the environment.

Overall, steel coil galvanizing lines play a crucial role in the steel industry by providing a range of benefits that enhance the quality, durability, and sustainability of steel products. From protecting against corrosion and enhancing aesthetic appeal to maintaining structural integrity and promoting environmental conservation, galvanizing lines are essential for ensuring the efficiency and effectiveness of the steel production process. By investing in steel coil galvanizing lines, steel manufacturers can not only improve the quality of their products but also contribute to a more sustainable and environmentally friendly industry.

Conclusion

Steel coil galvanizing lines offer a wide range of benefits, from increased corrosion resistance to improved aesthetics. By understanding the process and applications of these lines, manufacturers can make informed decisions about incorporating them into their production processes. Whether it's for automotive parts, construction materials, or everyday household items, galvanized steel plays a crucial role in our daily lives. As technology continues to evolve, so too will the capabilities of steel coil galvanizing lines, opening up even more possibilities for their use. In conclusion, investing in a steel coil galvanizing line is not just a smart business decision, but a step towards a more sustainable and efficient future in the manufacturing industry.