products

Product Introduction

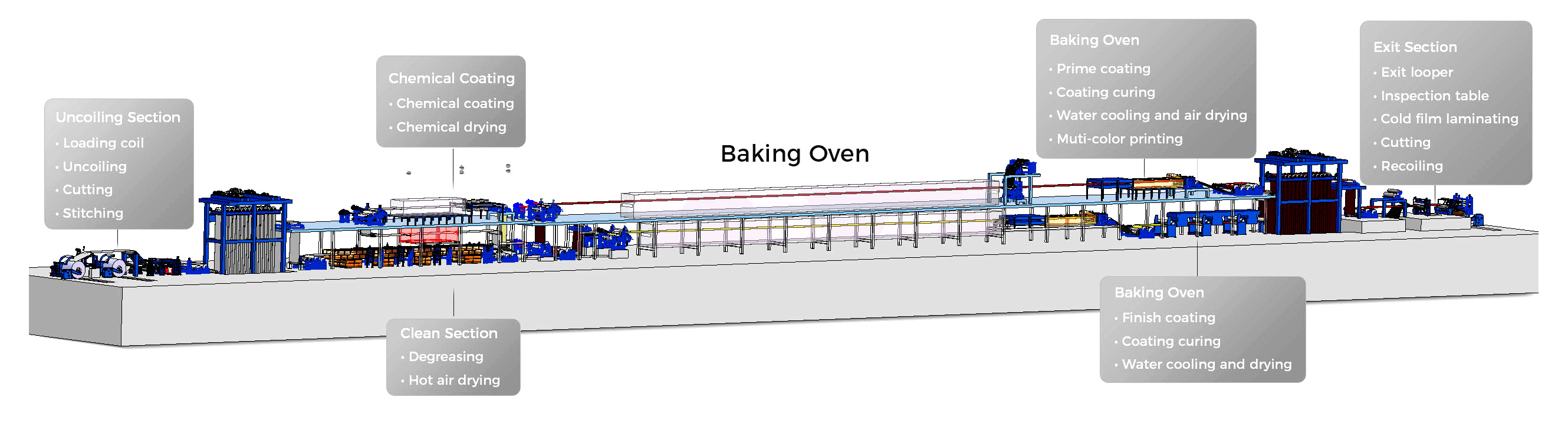

HiTo mission is to create the greatest value for our customers and grow into a leading Coil Color Coating line Manufacturer.

HiTo supply Production line for laminating organic polymer layer onto the surface of metal coils as substrates, it is laminating line, it finish product is PVF/PVC, PET/PVC coated metal coils(VCM, PEM) using high-valued applications or high-end interior decoration materials.

Laminating process using metal coils can be annealed cold-rolled coils, hot-dip galvanized coils, aluminium alloy coils, stainless steel coils etc.). HiTo Engineering has been manufacturing laminating Line since 2009 and has over 20 references worldwide.

advantages

Talk To Us About Your exclusive project

As one of the professional color coating line manufacturers, HiTo Engineering has completed over 10 Turnkey Coil Coating Production Line projects outside of China, becoming a Turnkey Coil Color Coating Equipment Solution Provider for more than 70 clients in the Chinese market. You can be assured that HiTo Engineering will find the right solution to fit your business needs.

raw material

The raw material coils for paint coating can be:

Application

The HiTo Laminating Line has various design features and can produce high-quality products suitable for the following markets:

HiTo Laminating Processing Parameters:

| Raw Material | Thickness (mm) | Width(mm) | Processing Speed | Finish Products | Energy |

| GI, GL, Annealed CR | 0.11 - 0.8 | 700-1550 |

10-30MPM |

Laminated Steel Coils |

CNG or LPG, Electric, DM Water |

| Aluminium Alloy Coils |

0.15 - 0.55 0.2-1.2 |

750-1250 900-1550 1000-1800 |

10-30MPM |

Laminated Aluminium Coils |

|

| Stainless Steel Coils | 0.1 - 0.4 | 700-1250 |

10-20MPM |

Laminated Stainless Steel Coils |

all Film With Coils Laminating Production Line Products

our service

HiTo Engineering provides the following services to you:

HiTo experience and operational expertise enable HiTo to ensure the quality of coating products on all HiTo Color Coating Production Line.