Carbon Coils Continuous Hot-dip Galvanizing Line Product Line Wholesale - HiTo Engineering

Product Overview

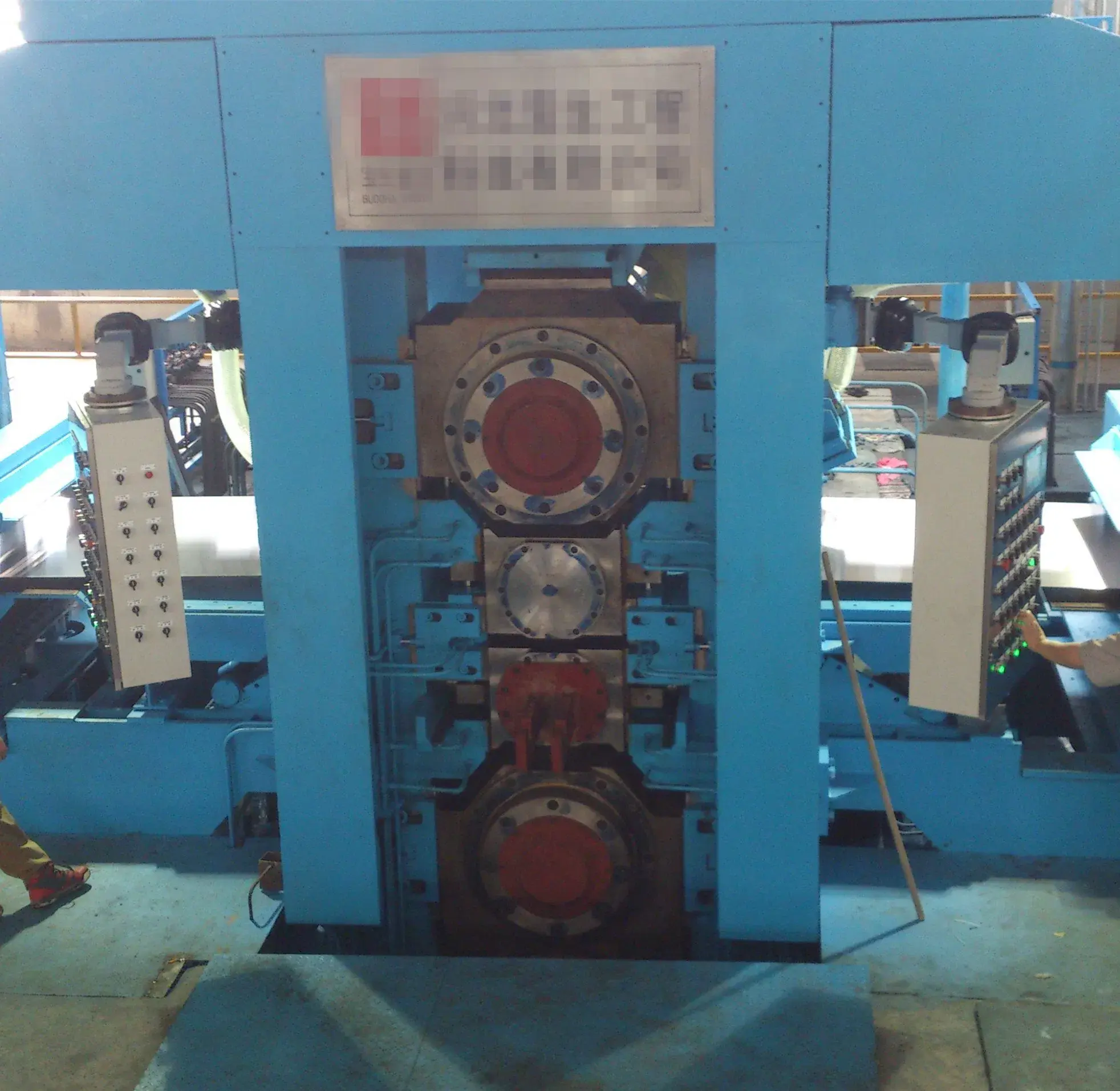

- This product is a carbon coils continuous hot-dip galvanizing line designed to plate zinc or aluminum alloy on strips at high temperatures. It includes various essential equipment such as uncoilers, welders, storage tanks, degreasing sections, continuous annealing furnaces, zinc pots, air knives, and more.

Product Features

- Equipped with steel chemical cleaning or high-efficiency electrolytic cleaning section.

- Combination of non-oxidizing (NOF) and radiant tube heating (RTH) for fast heating and high thermal efficiency.

- Strip cooling through protective gas cycling spray cooling for quick and uniform cooling.

- Includes straightening machine and finishing machine for improved product quality.

- Flue gas waste heat recovery technology to reduce energy consumption.

Product Value

- Certified for quality and safety, ensuring customer satisfaction.

- Innovative engineering team providing tailor-made solutions.

- Competitive pricing with world-class technology and ongoing specialist support.

Product Advantages

- Superior technology for plating zinc or aluminum alloy on strips.

- Fast and uniform strip cooling, improving product quality.

- Energy-saving features like waste heat recovery technology.

- Real-time coating thickness monitoring and precise adjustment.

Application Scenarios

- Ideal for cold rolled low carbon steel like SPCC, SPCD.

- Suitable for coating types like GI, GA, GF.

- Used for products like CQ, DQ, G550.

- Capacity ranges from 60,000-300,000 MT/yr.

- Perfect for industries requiring high-quality coating and efficient production processes.