Coil Coating Line Manufacturers Product Line Wholesale - HiTo Engineering

Product details of the coil coating line manufacturers

Product Specification

Origin: China

Trademark: HiTo

Transport Package: Container

HS Code: 8479819000

Type: Coating Production Line

Product Overview

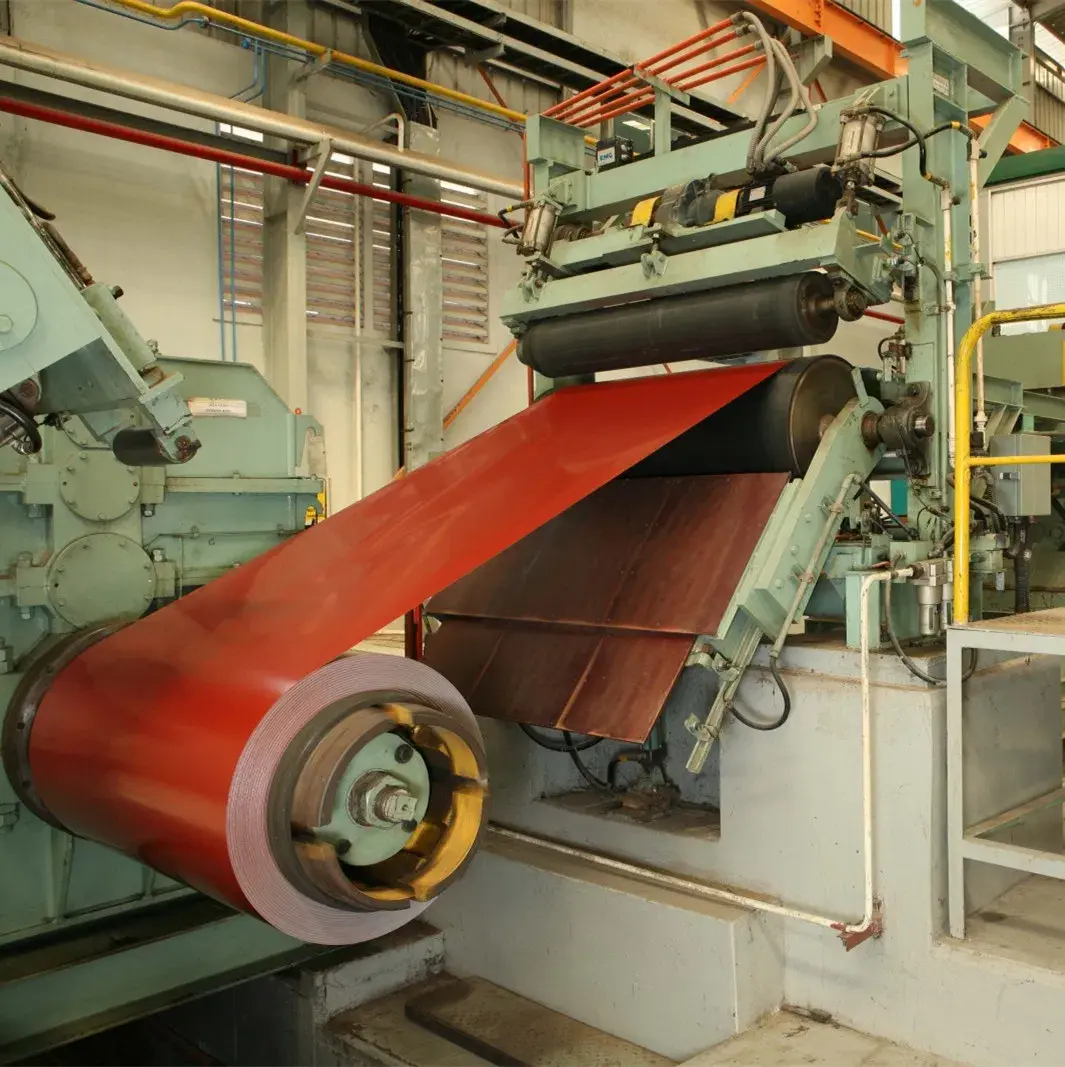

HiTo Engineering coil coating line manufacturers is made by highly skilled and experienced professionals. High quality parameters are enforced on this product. Our coil coating line manufacturers has a wide range of applications and can be used in a variety of situations and scenarios. As a major supplier for coil coating line manufacturers, Weifang HiTo Equipment Engineering Co.,Ltd has conducted strict quality tests before shipment.

Product Information

Compared with similar products, our coil coating line manufacturers is provided with the following competitive advantages.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip, 3-15Tons

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Process speed: 30 - 200m/min

- Production capacity: 30,000-300,000 Tonnes/year

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Advantages

Weifang HiTo Equipment Engineering Co.,Ltd has been engaged in research and development and production of coil coating line manufacturers since its establishment. Teams of experts are the strength of our company. They have knowledge not only in our own products and processes but also in those aspects of our customers. They are able to deliver the best for customers. HiTo Engineering insists on the desire to become a major influence supplier in the future. Get more info!

We are waiting for consulting from new and old customers!