Coil Color Coating Line Product Line Wholesale - HiTo Engineering

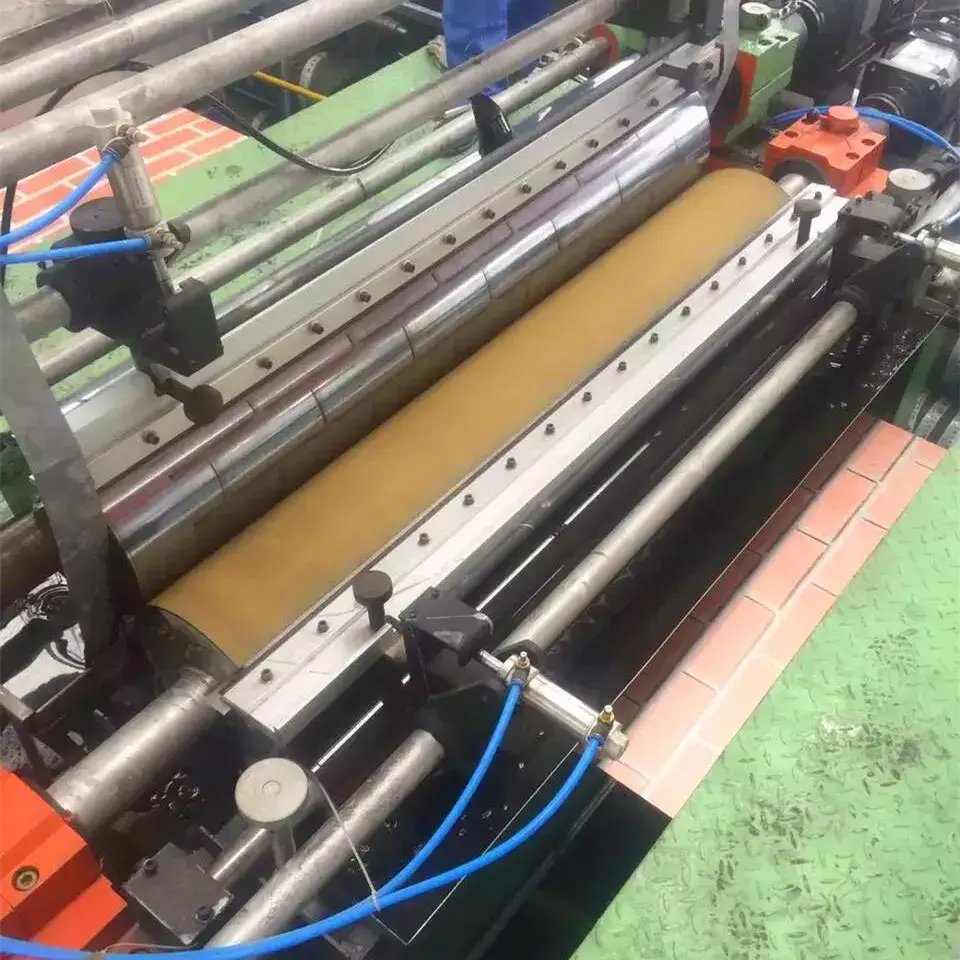

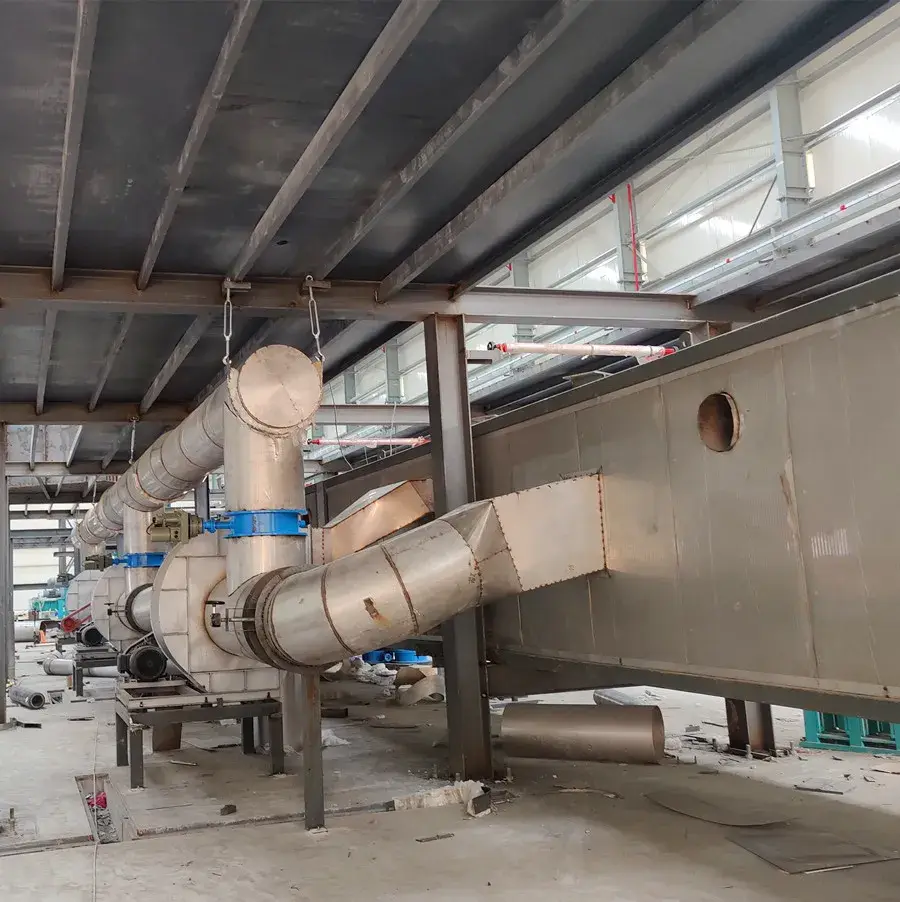

Product details of the coil color coating line

Product Specification

Production Capacity: 20 Sets/ Year

Origin: China

HS Code: 8479819000

Product Information

HiTo Engineering coil color coating line is finely produced by experienced production professionals using advanced technology. The product is approved by experts and has good performance, durability and practicality. The popularity and the reputation of HiTo Engineering have improved rapidly over the years.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip, 3-15Tons

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Process speed: 30 - 200m/min

- Production capacity: 30,000-300,000 Tonnes/year

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Advantage

• Rich in industry experience and professional in technique, HiTo Engineering's excellent talents provide constant motivation for continuous development.

• Our company was founded in We have been dealing with production and processing for years.

• HiTo Engineering is located in a position with traffic convenience. And the advantageous geographic location creates a broad prospect for the business development of our company.

• In recent years, our company has established a relatively complete sales system and actively explored new sales markets. The market share of products in the domestic market has been increased year by year.

Our company is committed to providing professional and quality products with affordable prices for customers. Welcome customers in need to contact us, and look forward to establishing a mutually beneficial relationship with you!