Product Overview

Certainly! Here is a summary of the “Colour Coating Line Specification by HiTo Engineering” under the five requested points:

Product Features

**Product Overview**

Product Value

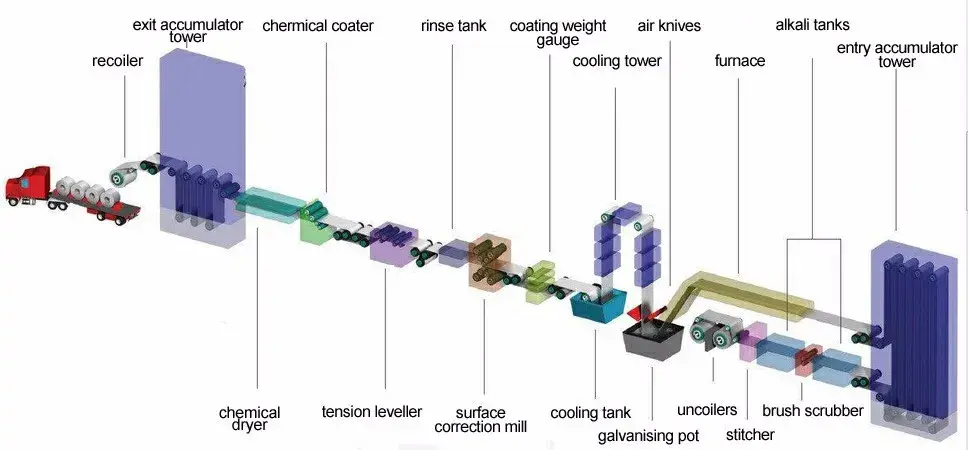

The Colour Coating Line by HiTo Engineering is a highly advanced production line designed for coating metal strips, including hot-dip aluminum and galvanized steel. It integrates multiple key equipment such as uncoilers, welders, annealing furnaces, zinc pots, and finishing machines to deliver high-quality coating solutions. The system supports various strip materials and thicknesses and emphasizes innovation in engineering to meet customized production goals and budgets.

Product Advantages

**Product Features**

Application Scenarios

- Equipped with advanced chemical and electrolytic cleaning sections for superior surface preparation.

- Uses a hybrid heating system combining non-oxidizing and radiant tube heating for fast, efficient, and accurate temperature control.

- Incorporates a protective gas cycling spray cooling system with variable frequency for uniform strip cooling after annealing.

- Features real-time coating thickness measurement and fingerprint-resistant coating capabilities to optimize surface quality.

- Employs waste heat recovery technology for energy savings and environmentally friendly operation.

- Uses vector frequency control, CPC and EPC correction, and field bus control to enhance automation and reliability.

**Product Value**

HiTo Engineering’s Colour Coating Line offers a world-class, tailor-made solution that improves production efficiency, product quality, and cost-effectiveness. The integration of energy-saving systems reduces operating expenses and environmental impact. Continuous specialist support ensures maximum uptime and customer satisfaction, giving manufacturers a competitive edge in global markets.

**Product Advantages**

- High technological sophistication balanced with competitive pricing.

- Enhanced product quality due to precise temperature control, effective cleaning, and uniform coating application.

- Energy-efficient operation through heat recovery and optimized heating processes.

- Flexible customization to meet diverse production needs and specifications.

- Robust and reliable system design with advanced control technologies and user-friendly interfaces in English.

**Application Scenarios**

This coating line is ideal for metal processing facilities focused on producing coated steel strips used in automotive parts, home appliances, construction materials, and electrical equipment. It suits manufacturers requiring consistent high-quality GI (galvanized iron), GA (galvalume), and other aluminum alloy coatings within a production capacity range of 60,000 to 300,000 metric tons per year, supporting a variety of steel grades and thicknesses.

---

If you need a more concise or detailed version, feel free to ask!