HiTo Engineering Coil Color Coating Line Coil Color Coating Line Factory

Product Overview

Certainly! Here is a summarized overview of the **HiTo Engineering Coil Color Coating Line** based on the provided detailed introduction:

Product Features

**Product Overview**

Product Value

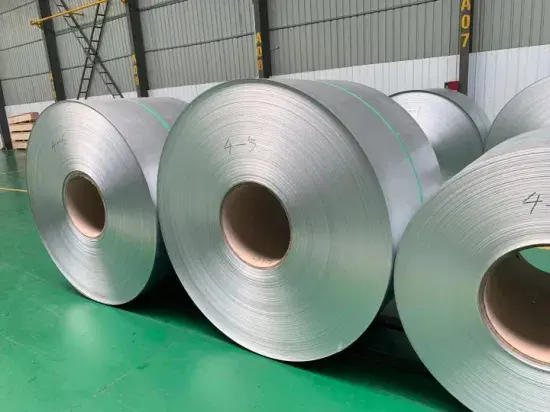

HiTo Engineering Coil Color Coating Line is an advanced color coating production line designed to provide customized, high-quality solutions tailored to meet individual production goals and budgets. Manufactured by Weifang HiTo Equipment Engineering Co., Ltd, it incorporates innovative technology with comprehensive specialist support to deliver world-class coating solutions for various metal coils.

Product Advantages

**Product Features**

Application Scenarios

- Utilizes a double-coating, double-baking model combined with hot air circulation heating for superior coating quality.

- Capable of processing a wide range of base materials including electro-galvanized, hot-dip galvanized, Al-Zn plated, cold-rolled steel, and aluminum coils.

- Supports strip thicknesses from 0.12 to 1.8 mm and widths between 600 to 1650 mm.

- High processing speeds ranging from 30 to 200 meters per minute.

- Features an optional Pattern Printing System for decorative finishes such as wood grain, marble, and brick patterns.

- Software and Human-Machine Interface (HMI) are fully provided in English for ease of use.

**Product Value**

The line enables manufacturers to achieve high-volume production capacity (30,000 to 300,000 tonnes per year) with consistent coating quality and precision. Its flexibility and customization options enhance production efficiency, reduce costs, and improve product aesthetics, thus giving customers a strong competitive edge in their markets.

**Product Advantages**

- Advanced technology integration offering top-tier coating quality at competitive pricing.

- Full range of professional services including project feasibility, equipment design, installation, commissioning, operator training, and ongoing technical support.

- Excellent thickness control with both general and high precision tolerance levels to meet diverse customer quality standards.

- Robust production capacity and versatility in processing multiple base materials and coil sizes.

- English-language programming and control interface increase accessibility and user-friendliness globally.

**Application Scenarios**

Ideal for industries requiring coated metal coils such as construction, home appliances, automotive, furniture, and decorative panels. The inclusion of pattern printing expands its use to architectural panels and decorative steel products, enabling manufacturers to serve various market demands from industrial to aesthetic applications.

---

If you would like, I can also help prepare promotional or technical material based on this summary.