HiTo Engineering Colour Coating Lines Makers

Product Overview

Certainly! Here is a summary of the “HiTo Engineering Colour Coating Lines Makers” based on the detailed introduction:

Product Features

**Product Overview:**

Product Value

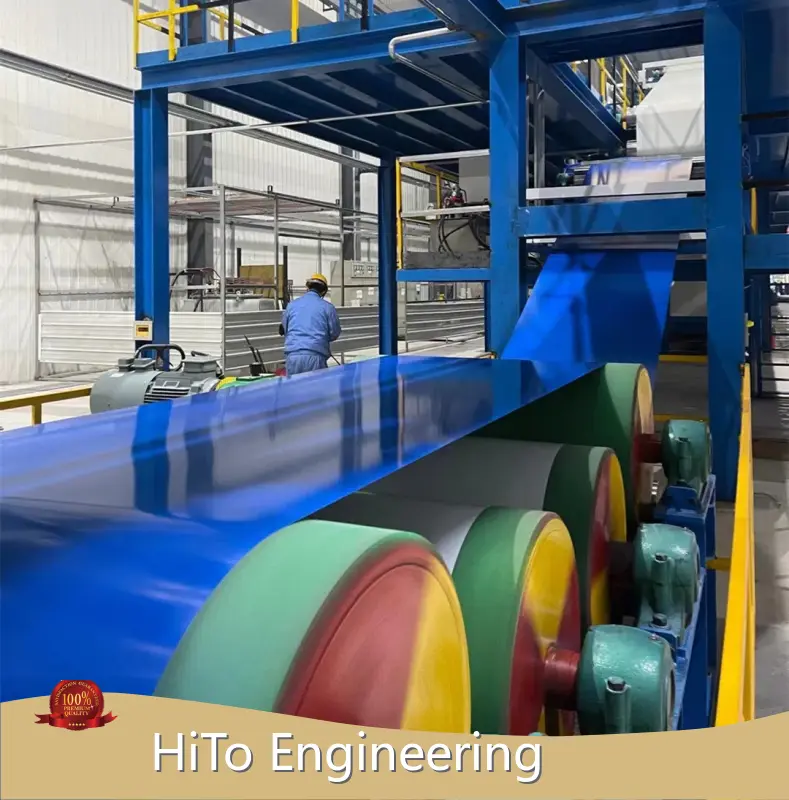

HiTo Engineering Colour Coating Lines Makers are advanced machinery designed for the continuous color coating of metal strips such as cold-rolled steel, aluminum coils, and galvanized plates. The product features a double-coating and double-baking process combined with hot air circulation heating, enabling high-speed production and precise coating for a variety of base materials with thicknesses ranging from 0.12 to 1.8 mm and widths between 600 and 1650 mm.

Product Advantages

**Product Features:**

Application Scenarios

- Utilizes a sophisticated double-coating and double-baking model with hot air circulation for consistent quality.

- Compatible with multiple base materials (electro-galvanized, hot-dip galvanized, Al-Zn plates, cold rolled steel, aluminum).

- High production speed (30-200 m/min) with an annual capacity of 30,000 to 300,000 tonnes.

- Offers pattern printing capabilities for decorative finishes such as wood grain, marble, or brick patterns.

- Software and HMI interface are fully in English for user convenience.

- Thickness tolerance is tightly controlled with options for general and high precision measurements.

**Product Value:**

HiTo’s color coating lines deliver cost-effective solutions by combining world-class technology with competitive pricing. The equipment enhances product quality and consistency, helping manufacturers meet diverse market demands and maintain a strong competitive edge. Comprehensive services including project feasibility, design, installation, training, and ongoing technical support add significant value to customers’ investments.

**Product Advantages:**

- Tailor-made engineering solutions adapted to specific client requirements and production goals.

- Strong innovation focus from an expert engineering team ensures cutting-edge technology.

- Robust after-sales support, including commissioning, operator training, technology transfer, and continuous technical assistance.

- Flexibility in configuration to meet various customer preferences.

- High reliability and performance driven by premium materials and precise process control.

**Application Scenarios:**

This color coating line is suitable for manufacturing decorative and functional coated metal sheets used in industries such as construction (roofing, cladding), appliance manufacturing, automotive parts, furniture, and packaging. It supports customers producing high-quality coated steel and aluminum strips required for both aesthetic and protective purposes across diverse market segments worldwide.