HiTo Engineering Continuous Galvanized Line Continuous Galvanized Line Company

Product Overview

Here is the summary of the “HiTo Engineering Continuous Galvanized Line” based on the detailed introduction:

Product Features

**Product Overview:**

Product Value

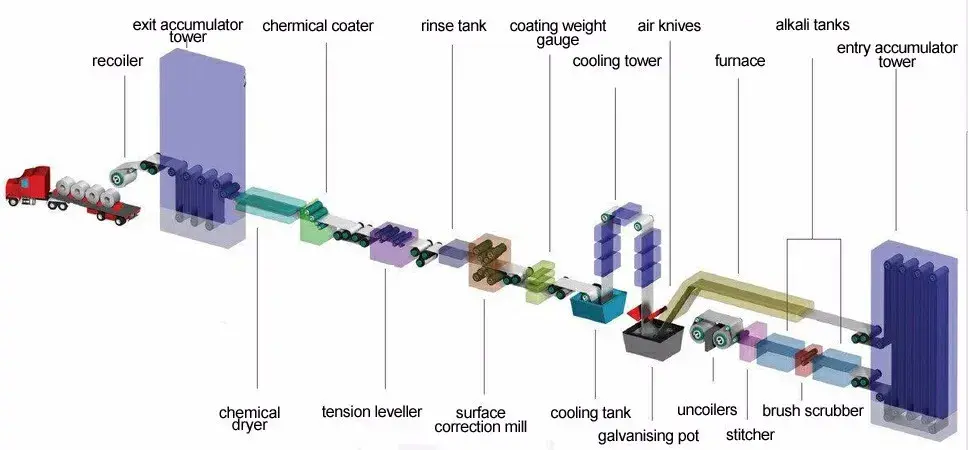

The HiTo Engineering Continuous Galvanized Line is a highly engineered production line designed for continuous hot-dip galvanizing of steel strips with zinc or aluminum alloys. It supports various steel specifications and thicknesses, ensuring high-quality coating with zero defects. The line is produced by Weifang HiTo Equipment Engineering Co., Ltd., combining advanced technology and stringent quality control to deliver reliable and versatile performance suitable for many industries.

Product Advantages

**Product Features:**

Application Scenarios

- Integration of advanced cleaning methods, including steel chemical and electrolytic cleaning with unique technologies to avoid secondary pollution.

- Combined heating system using non-oxidizing and radiant tube heating with precise air-fuel ratio control for fast and efficient heating.

- Protective gas cycling spray cooling with variable frequency control for uniform temperature regulation.

- High precision finishing equipment improving surface quality and mechanical properties of the coated steel.

- Waste heat recovery systems to enhance energy efficiency and reduce consumption.

- Use of ceramic induction heating zinc pot for uniform coating and longevity, along with advanced surface accuracy features.

- Real-time coating thickness measurement and fast-switching fingerprint-resistant coating capabilities.

- Modern control system featuring vector frequency control, CPC and EPC correction, and user-friendly human-machine interface in English.

**Product Value:**

The continuous galvanized line offers a competitive edge by combining world-class technology with cost-effective pricing and ongoing technical support. It ensures superior product quality, energy savings, and operational reliability, which translates into higher production efficiency, reduced waste, and adaptability to various customer needs. Customizable configurations allow alignment with specific production goals and budgets, increasing overall return on investment.

**Product Advantages:**

- Zero-defect production guaranteed by professional quality control throughout the process.

- Energy-efficient operation through advanced heat recovery and optimized heating and cooling systems.

- High-speed processing capacity (up to 260 meters per minute) and large annual output (60,000-300,000 MT), supporting high-volume industrial production.

- Sophisticated control and measurement systems enable precise coating thickness and surface quality control.

- Flexible design allowing customization and scalability for different steel grades, thicknesses, widths, and coating types.

**Application Scenarios:**

This continuous galvanized line is ideal for industries requiring corrosion-resistant steel strips, such as home appliances, automotive manufacturing, construction materials, electrical enclosures, and other industrial applications. Its ability to process cold-rolled low carbon steel with diverse coating options (GI, GA, GF) makes it suitable for a wide range of products that demand high-quality metal coatings with excellent mechanical properties and surface finish.