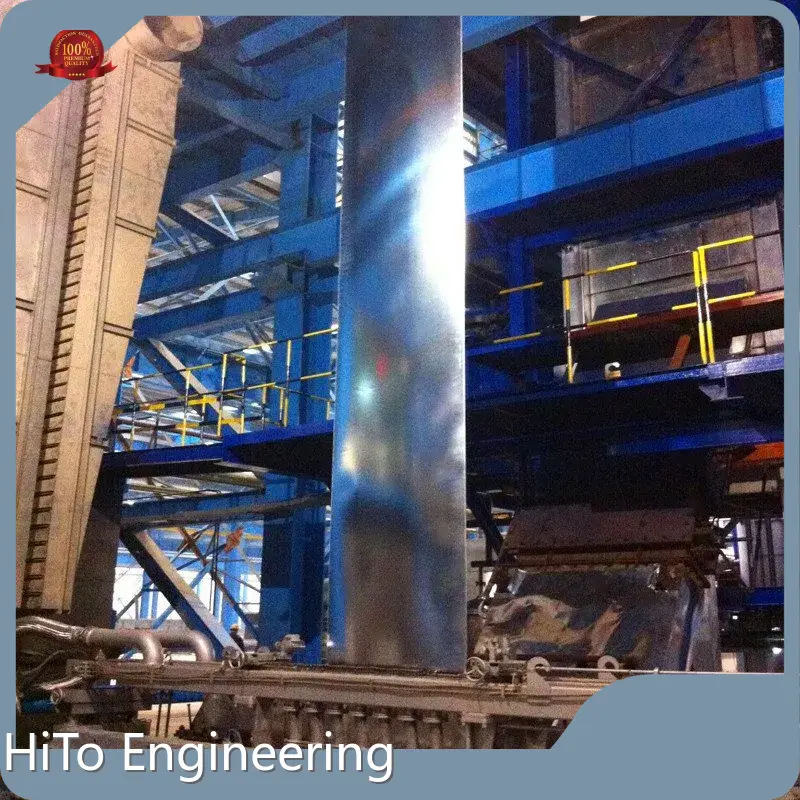

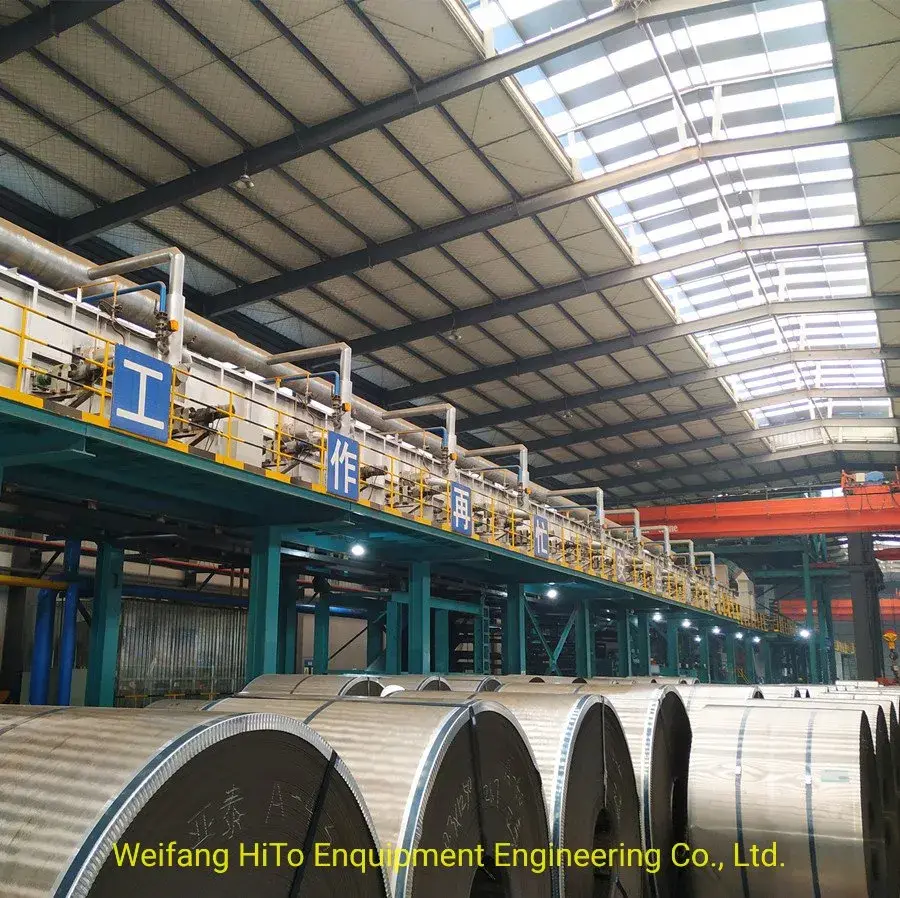

Hot Dip Galvanizing Line Manufacturer by HiTo Engineering

Product Overview

Certainly! Here is a summarized description of the “Hot Dip Galvanizing Line Manufacturer by HiTo Engineering” based on the provided details:

Product Features

**Product Overview**

Product Value

HiTo Engineering’s hot dip galvanizing line is an advanced production line designed for coating steel strips with zinc or aluminum alloy at high temperatures. It integrates multiple equipment including uncoilers, welders, degreasing sections, annealing furnace, zinc pot, air knife, and recoilers to produce galvanized steel with excellent surface quality. The line supports materials like cold rolled low carbon steel with thickness ranging from 0.12 to 3.0 mm and widths up to 1550 mm, operating at speeds up to 260 meters per minute.

Product Advantages

**Product Features**

Application Scenarios

- Utilizes advanced cleaning technologies combining chemical and electrolytic methods for superior surface preparation.

- Incorporates a fast and energy-efficient heating system using non-oxidizing and radiant tube heating techniques with precise temperature control.

- Features protective gas cooling and high-pressure jet cooling for uniform temperature regulation post-annealing.

- Equipped with sophisticated straightening and finishing machinery to enhance surface and mechanical properties.

- Employs cutting-edge flue gas waste heat recovery and induction heating zinc pot technologies to improve energy efficiency and product quality.

- Real-time coating thickness monitoring and fingerprint-resistant coating systems optimize product consistency.

- Uses vector frequency control, CPC and EPC correction, and fieldbus control systems for stable and user-friendly operation, with software and HMI fully in English.

**Product Value**

This galvanizing line offers high-quality, tailored galvanizing solutions that increase product competitiveness by improving coating uniformity, surface finish, and mechanical properties. The energy-saving technologies reduce operational costs, while the modular and scalable design allows for customization to meet different production goals and budgets. The comprehensive support ensures reliable operation and long-term investment protection.

**Product Advantages**

- High precision and automation ensure superior product quality and process control.

- Energy-efficient design reduces consumption and environmental impact through waste heat recovery.

- Advanced cleaning and coating technologies minimize defects and enhance adhesion.

- Flexible configuration options to suit various steel grades and coating requirements.

- Strong engineering support and use of trusted raw materials guarantee durability and reliable performance.

**Application Scenarios**

The hot dip galvanizing line is suitable for industries requiring corrosion-resistant steel products such as automotive manufacturing, construction materials, home appliances, electrical equipment, and general steel fabrication. It is ideal for producing galvanized steel strips used in structural components, panels, and parts that demand high durability and quality coatings.