Product Overview

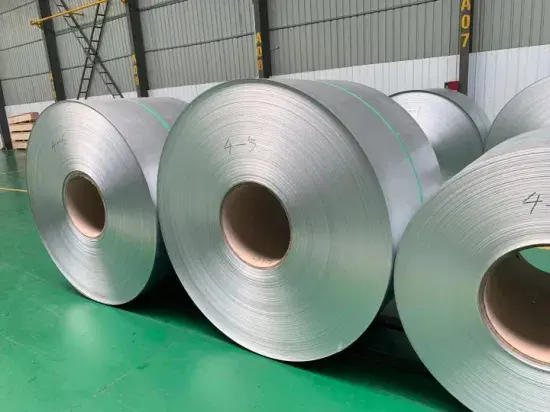

- The OEM Galvanizing Line Equipment is designed to coat galvanized steel in various coatings such as GI, GA, and GF, with a capacity of 60,000-300,000 MT/Y.

- The production line includes equipment such as uncoilers, degreasing sections, continuous annealing furnaces, zinc pots, air knives, tension levelers, and more.

Product Features

- Equipped with advanced technology such as non-oxidizing (NOF) and radiant tube heating (RTH) for fast heating and high thermal efficiency.

- Utilizes protective gas cycling spray cooling for uniform strip cooling and precise temperature control.

- Features a straightening machine and finishing machine to improve product surface quality and mechanical properties.

Product Value

- Offers a world-class supply solution with cutting-edge technology at competitive pricing.

- Provides ongoing specialist support and ensures consistent and long-lasting performance.

Product Advantages

- Energy-saving features include a heat recovery system from waste gas and flue gas waste heat recovery technology.

- Offers precise coating thickness monitoring and adjustment capabilities, as well as fingerprint-resistant coating machines for optimized equipment layout.

Application Scenarios

- Ideal for coating galvanized steel strips, including cold rolled low carbon steel, with thicknesses ranging from 0.12-2.5mm and widths from 700-1550mm.

- Widely used in industries requiring high-quality galvanized coatings, such as automotive, construction, and appliance manufacturing.