The raw materials of Color Coating Line,Colour Coating Line,Coil Coating Line,Coils Coating Line,Paint Coating Line,Paint Coating Line is purchased by a professional team.

HT-CCL

HiTo

847981

Weifang HiTo Equipment Engineering Co.,Ltd supply continuous color coating line and continuous hot-dip galvanizing line.

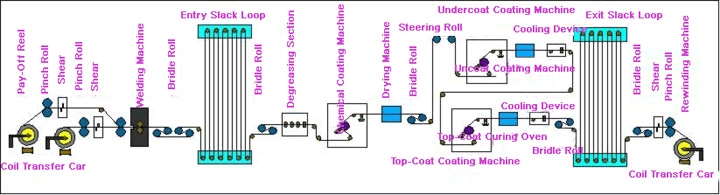

This is a pre-coating line that forms coats through advance application and baking of coating materials onto strips produced by Continuous Galvanizing Lines (CGL; to enhance corrosion resistance) and Continuous Annealing Lines (CAL; to improve properties, such as strength and elongation). It is an add-on for visual aspects of strips, such as color and gloss, as well as for protective elements, such as weather and corrosion resistance.

Product Overview:The Color Coating Line is the process of coating a sheet with organic paint. The coated sheet has good characteristics of printing, forming, corrosion resistance and decoration, and it still keeps the performance of high strength and deformability. The production of color coating sheets with high quality and multi-function has developed recently, and the sheet with high corrosion resistance, high deformability, fingerprint resistance and microbial resistance will share part of the market.

EQUIPMENT PARAMETERS:

1. Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate etc.

2. raw material: cold rolled strip, GI, GL, aluminum strip

3. Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

4. Outer diameter of steel coil: φ800-1800mm

5. Process speed: 30 - 200m/min

6. Coating thickness: 5-25μm for the single-layer dry film on the front face (regulated as required), 5-15μm for the single-layer dry film on the back face (regulated as required)

7. Production capacity: 50,000-200,000 Tonnes/year

8. Energy type: electricity, natural gas, liquefied petroleum gas, coal gas, etc.

HiTo Color Coating Line Manufacturers also provide coil printing technology within our CCL.

Color Coating Line, Colour Coating Line, Coil Coating Line, Paint Coating Line is carefully chosen from top grade suppliers.