Product details of the coating line

Product Specification

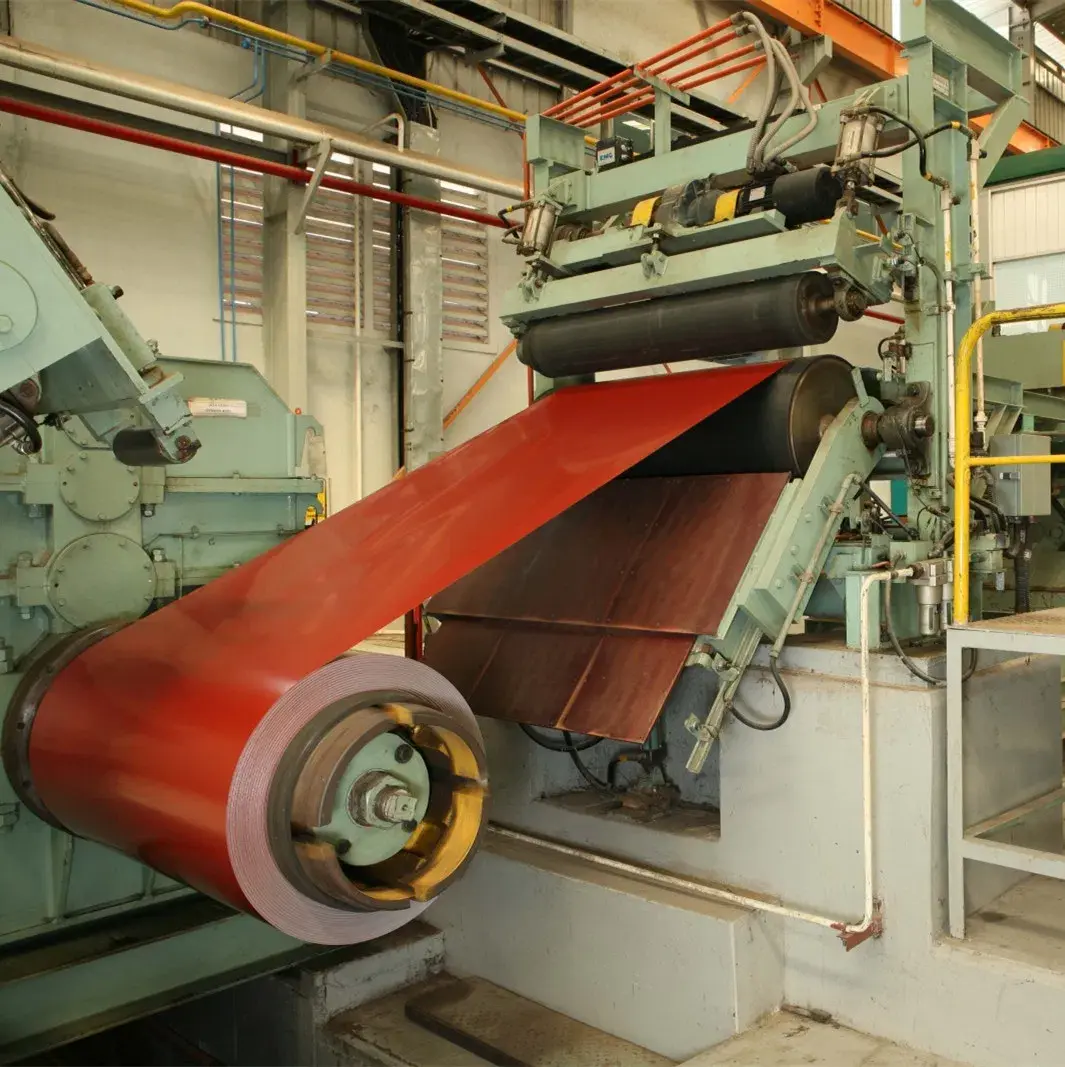

Coating: Coil Coating

Trademark: HiTO

Condition: New

Specification: 1600CBM

Product Introduction

The raw materials of HiTo Engineering coating line are paid 100% attention during selecting. The defective raw materials are all eliminated before entering the factory and thus they are of high performance. The implementation of the complete quality management system greatly guarantee that the product is manufactured according to the international quality standards. Carrying out strict quality assurance is beneficial to the popularity of coating line.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip, 3-15Tons

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Process speed: 30 - 200m/min

- Production capacity: 30,000-300,000 Tonnes/year

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Advantage

• HiTo Engineering's are favored and supported by the market, with an annual increment of market share. They are not only sold well in various regions of the country, but also exported to different foreign countries.

• Established in HiTo Engineering accumulated rich industry experience after exploring for years.

• HiTo Engineering has an experienced and professional technical team to provide technical support for the R&D and production of products.

• Based on good business reputation, high-quality products, and professional services, HiTo Engineering wins unanimous praise from domestic and foreign customers.

Our company is committed to providing professional and quality products with affordable prices for customers. Welcome customers in need to contact us, and look forward to establishing a mutually beneficial relationship with you!