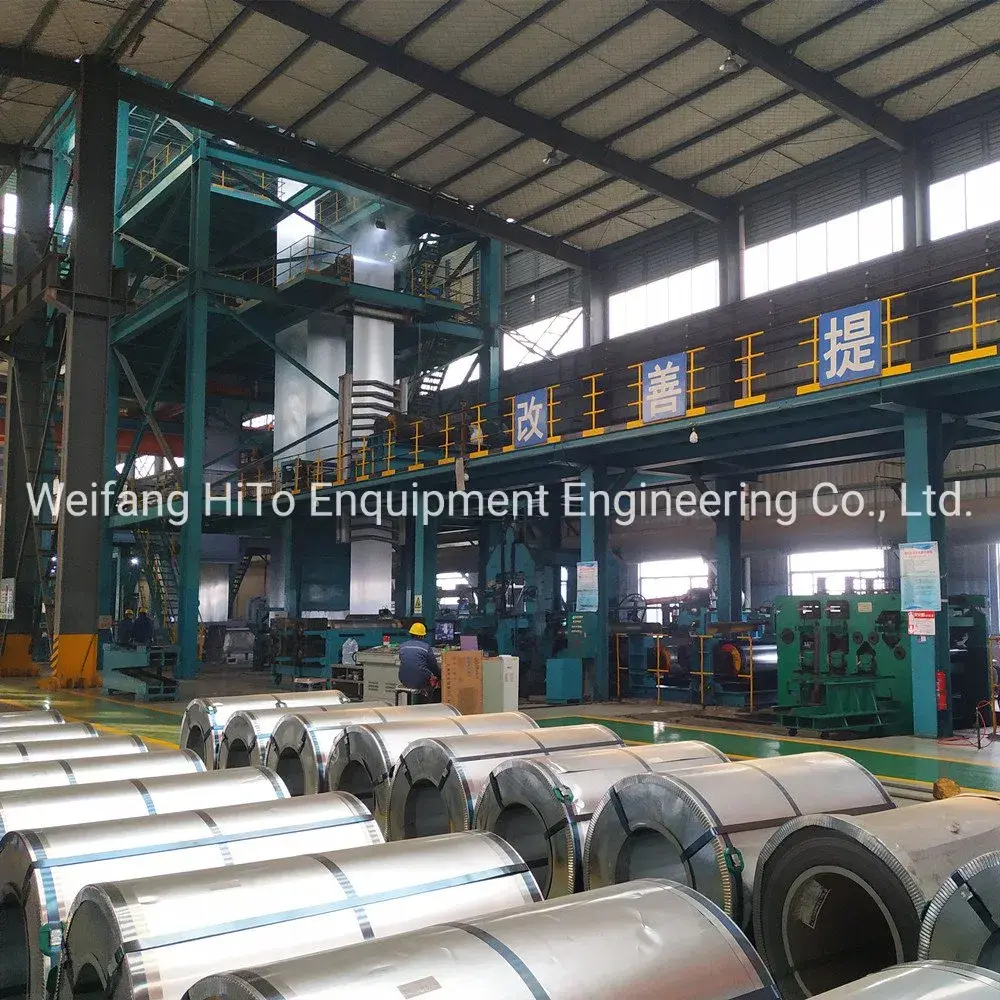

Carbon Coils Continuous Hot-dip Galvanizing Line Carbon Coils Continuous Hot-dip Galvanizing Line Wholesale - HiTo Engineering

Product Overview

Certainly! Here is a summarized description of the “Carbon Coils Continuous Hot-dip Galvanizing Line” by HiTo Engineering, divided into the requested five points:

Product Features

**Product Overview**

Product Value

The Carbon Coils Continuous Hot-dip Galvanizing Line is a steel coating production line designed to apply a high-quality galvanized or aluminum-zinc alloy coating on carbon steel coils. It supports a capacity range of 60,000 to 300,000 metric tons per year and processes steel substrates with thicknesses from 0.12 to 2.5 mm and widths between 700 to 1550 mm.

Product Advantages

**Product Features**

Application Scenarios

- Advanced cleaning section with combined horizontal and vertical spray plus electrolytic cleaning for superior surface preparation.

- Fast and energy-efficient heating via a combination of non-oxidizing and radiant tube heating with refined air-fuel ratio controls.

- Protective gas cycle cooling with high-pressure jets ensures uniform temperature control before coating.

- Use of jet-type ceramic induction heating zinc pot enhances coating uniformity and extends equipment life.

- Real-time coating thickness monitoring and fingerprint-resistant coating options optimize product quality.

- Vector frequency control and advanced control technologies with user-friendly English-language interface.

**Product Value**

This production line delivers superior surface quality, high durability, and precise coating thickness control, which enhances the finished product’s corrosion resistance and mechanical properties. Its energy-saving waste heat recovery system lowers operational costs, and tailor-made solutions ensure alignment with individual production goals and budgets, providing competitive advantages in both quality and cost-efficiency.

**Product Advantages**

- Uses world-class technology with rigorous raw material selection ensuring consistent product performance.

- Combines multiple sophisticated processes and equipment such as continuous annealing furnace, tension leveling, and coagulating systems enhancing product flatness and coating adhesion.

- Advanced energy recovery reduces consumption and environment impact.

- Comprehensive specialist support and customizable configurations are available to meet diverse customer demands.

- High line speeds (up to 260 meters per minute entry/exit) facilitating large volume and efficient production.

**Application Scenarios**

Ideal for manufacturers involved in producing galvanized steel coils for various industries such as automotive, home appliances, construction, electrical cabinets, and furniture. It suits large-scale continuous production environments where high-quality zinc or aluminum alloy coatings are required for corrosion protection, surface finishing, and improved mechanical properties of low carbon cold-rolled steel substrates.