Product details of the coating line

Product Specification

Specification: 1600CBM

Transport Package: Container

Origin: China

Type: Coating Production Line

Quick Detail

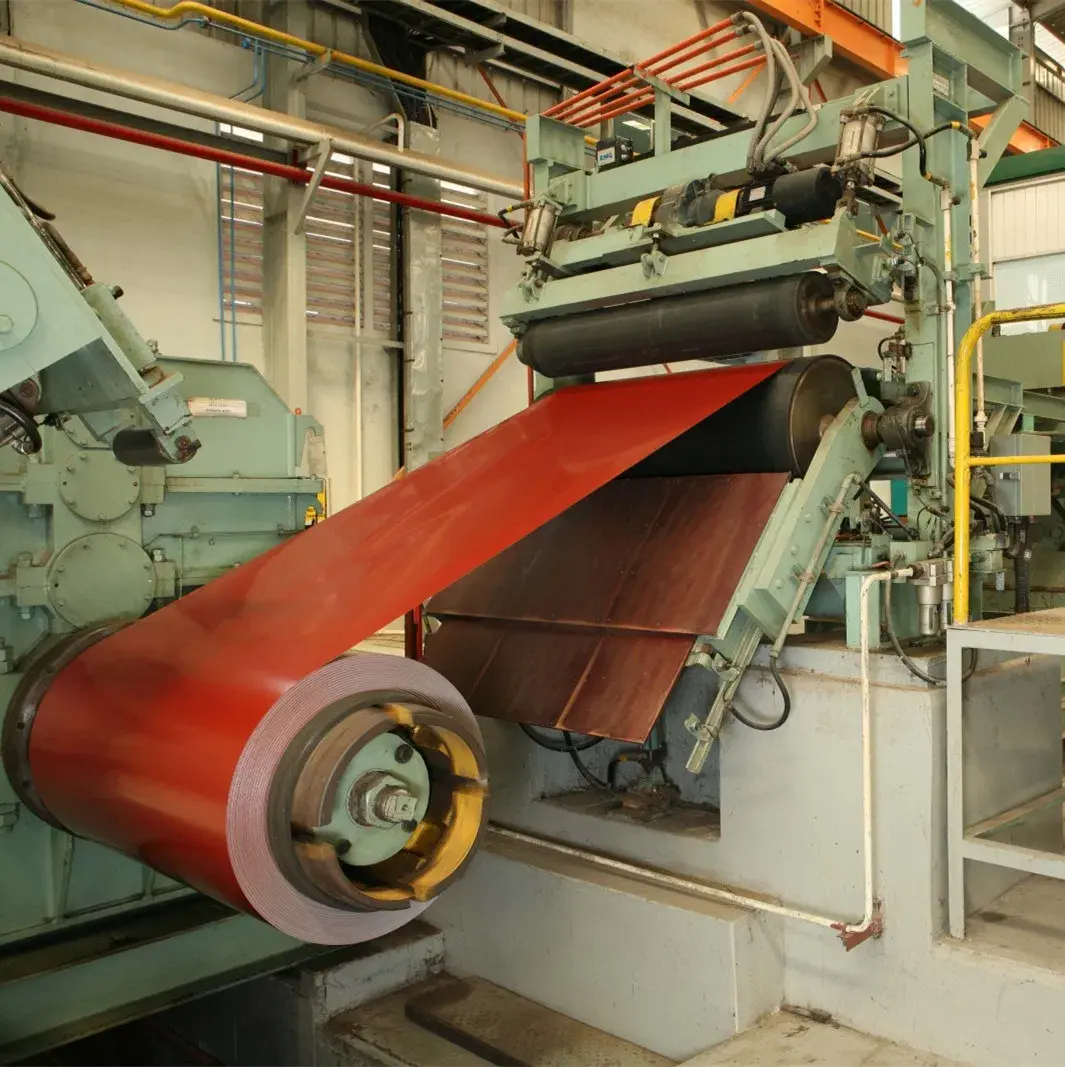

HiTo Engineering coating line is made of high-grade raw materials and manufactured by using cutting-edge technology in complete compliance with industry production standards. What distinguishes the product from others is the reliable quality, stable performance, and long service life. Weifang HiTo Equipment Engineering Co.,Ltd has extensive design capabilities, rigorous process, a complete quality control system and good after-sales service.

Product Introduction

The coating line of HiTo Engineering has been improved greatly in the following aspects.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip, 3-15Tons

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Process speed: 30 - 200m/min

- Production capacity: 30,000-300,000 Tonnes/year

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Introduction

Weifang HiTo Equipment Engineering Co.,Ltd is a company specializing in the production of We operate our business in accordance with standards and our office is located in HiTo Engineering is capable of providing customers with high-quality products and thoughtful services relying on the professional service team. Do not hesitate to contact us if you are interested in our