Coil Processing Line by HiTo Engineering

Product Overview

Certainly! Here is a summarized description of the “Coil Processing Line by HiTo Engineering” based on the detailed introduction:

Product Features

**Product Overview**

Product Value

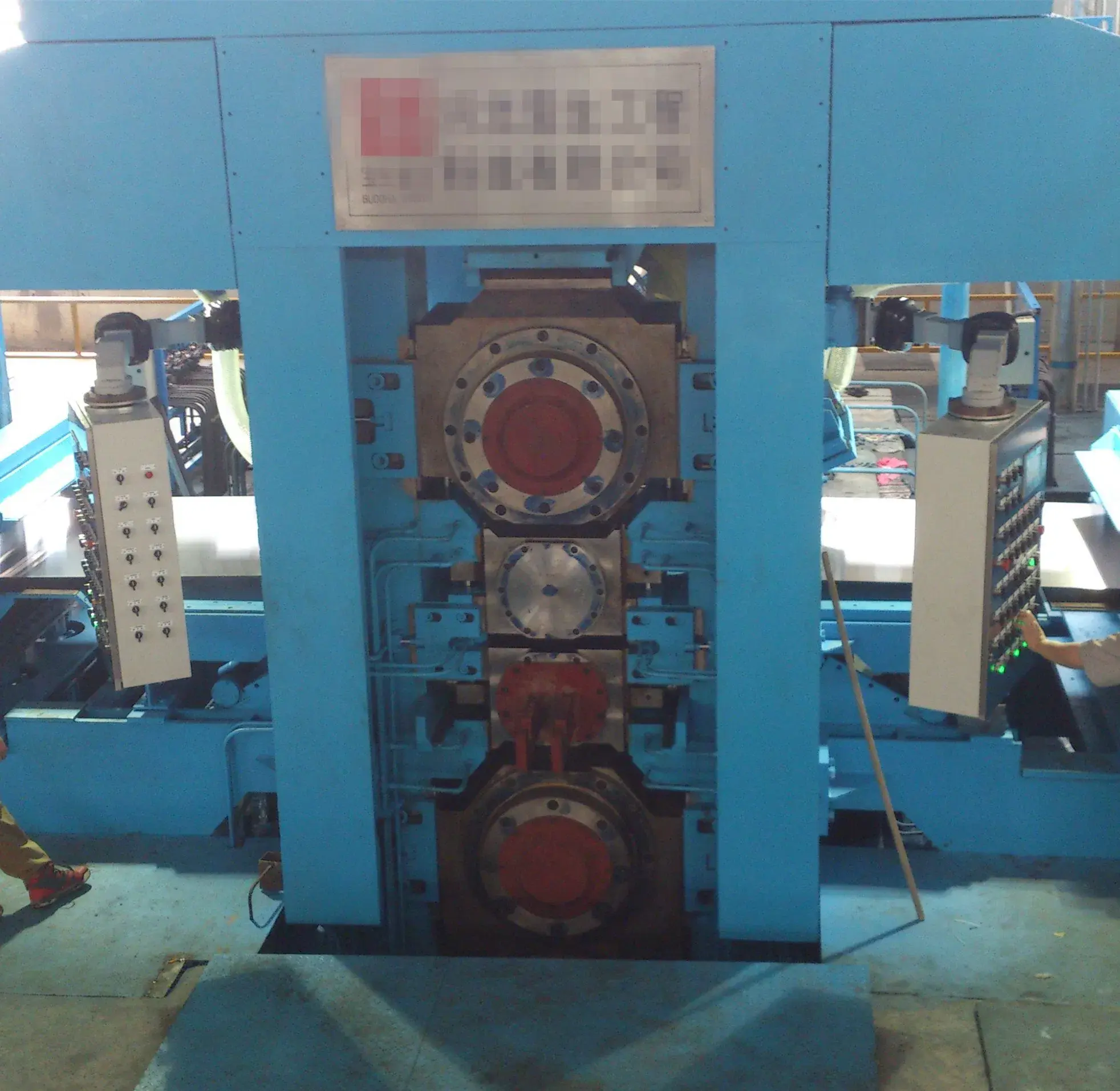

The HiTo Engineering Coil Processing Line is a high-capacity coating production line designed for processing cold-rolled low carbon steel coils with thicknesses ranging from 0.12 to 2.5 mm and widths between 700 to 1550 mm. It incorporates advanced equipment such as uncoilers, welders, annealing furnaces, zinc pots, and recoilers to produce galvanized and aluminized strips (GI, GA, GF coatings) with an annual capacity between 60,000 to 300,000 metric tons. The system features a modern, aesthetically appealing design with optimum operational performance and energy-saving technologies.

Product Advantages

**Product Features**

Application Scenarios

- Advanced cleaning sections combining chemical and electrolytic methods for superior surface preparation and pollution control.

- Innovative heating technologies including non-oxidizing and radiant tube heating for fast and efficient annealing with enhanced insulation and longer equipment life.

- Protective gas cycling spray cooling with variable frequency control for precise temperature management.

- High precision machinery for straightening, coating, and finishing to improve surface quality, shape, and mechanical properties.

- Real-time coating thickness measurement and optimized air knife control.

- Jet-type ceramic induction heating zinc pot for uniform heating and minimal slag formation.

- Utilizes flue gas waste heat recovery systems to improve energy efficiency and reduce operational costs.

- Modern control system with vector frequency control, CPC/EPC correction, and user-friendly English-language HMI.

**Product Value**

The coil processing line offers tailored, high-quality production solutions enabling customers to meet specific production goals, quality standards, and budget requirements. It supports large-scale, efficient galvanized and aluminized coil manufacturing, delivering consistent product quality that meets international standards (SPCC, SPCD, JIS G 3141, JIS G 3302). The energy-saving technologies and robust engineering backing ensure reduced operational costs and enhanced competitiveness.

**Product Advantages**

- World-class technology at competitive prices supported by dedicated, ongoing specialist service.

- Comprehensive production capabilities covering the full coil processing spectrum from cleaning to coating and finishing.

- Superior environmental and safety features reducing pollution and improving operational safety.

- High automation and control precision increasing production efficiency and product consistency.

- Flexibility allowing configuration customization to meet diverse customer requirements.

- Long service life with reduced downtime due to advanced materials and design innovations.

**Application Scenarios**

The coil processing line is ideally suited for industries requiring galvanized or aluminized steel coils, including automotive, construction, home appliances, electrical equipment, and machinery manufacturing. It is used in large-scale steel plants and coating facilities that demand high-quality surface treatment, excellent corrosion protection, and precise coating thickness control. The technology is especially beneficial where energy efficiency and environmental compliance are critical.