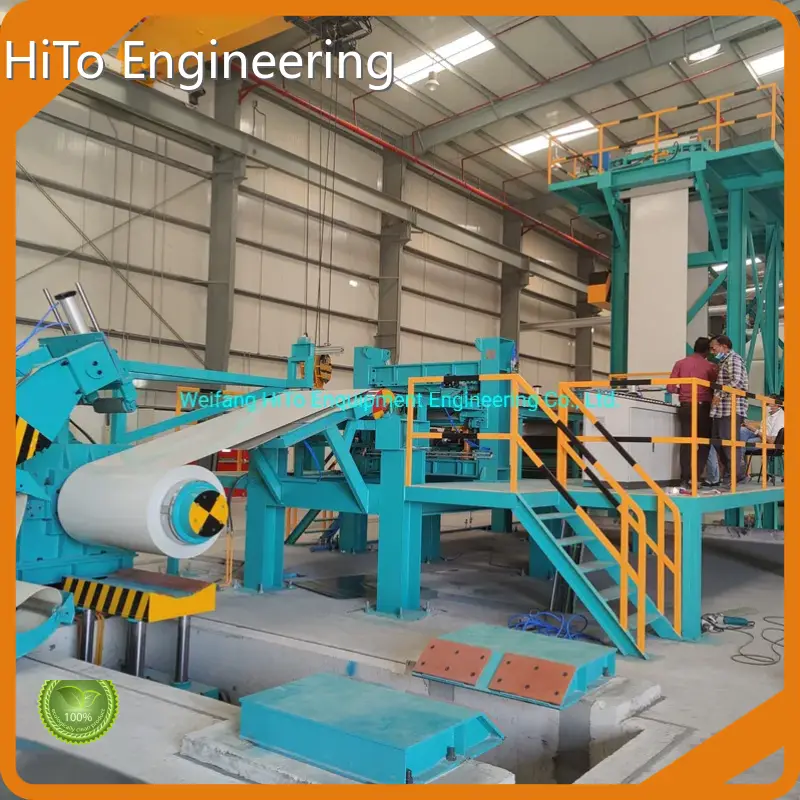

Product Line Coil Processing Line Suppliers

Product details of the coil processing line

Product Specification

Width: 700-1550mm

Raw Material: Gi, Gl, Al, Ss

Origin: China

Certification: ISO

Type: Coating Production Line

Product Information

Our design for coil processing line is very fashionable and special. Long service life absolutely manifests its superior performance. As we adhere to continuous innovation, the product will be given more advantages and will be more widely used in the future.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Outer diameter of steel coil: φ800-2000mm

- Process speed: 30 - 200m/min

- Coating thickness : 5-25μm for the single-layer dry film on the front face (regulated as required) 5-15μm for the single-layer dry film on the back face (regulated as required)

- Production capacity: 30,000-300,000 Tonnes/year

- Energy type: electricity, natural gas, liquefied petroleum gas, etc.

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Feature

• HiTo Engineering's products are sold to many central cities in China. They are also exported to North America, Europe, Australia, and Southeast Asia.

• HiTo Engineering was founded in As an enterprise with strong economic power, we have been insisting on keeping pace with the times and constantly pursuing for excellence during years.

• With the rapid development of the economy, customer service management no longer merely belongs to the core of service-oriented enterprises. It becomes the key point for all enterprises to be more competitive. In order to follow the trend of the times, HiTo Engineering runs an outstanding customer service management system by learning advanced service idea and know-how. We promote customers from satisfaction to loyalty by insisting on providing quality services.

• HiTo Engineering is located in a place with traffic convenience. There are highways, railways, and airports.

Our company is committed to providing professional and quality products with affordable prices for customers. Welcome customers in need to contact us, and look forward to establishing a mutually beneficial relationship with you!