HiTo Engineering Colour Coating Line Specification Makers

Product Overview

Here is a summary of the "HiTo Engineering Colour Coating Line Specification Makers" based on the detailed product introduction:

Product Features

**Product Overview**

Product Value

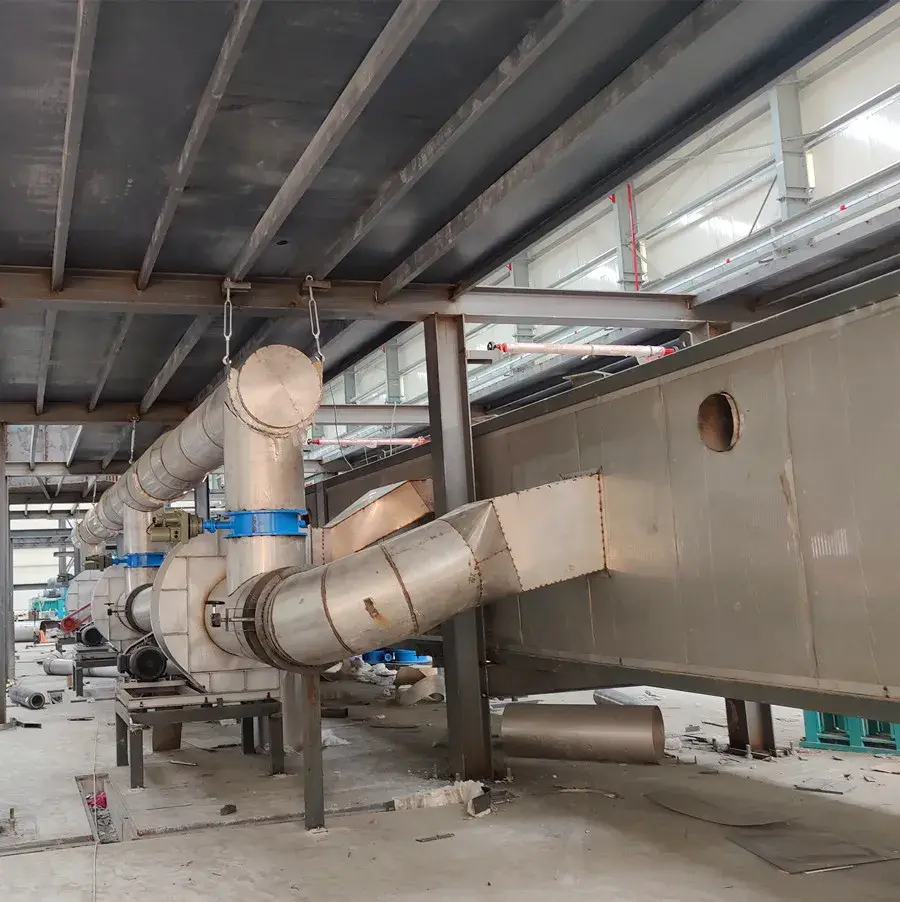

HiTo Engineering Colour Coating Line Specification Makers is an advanced industrial solution designed to provide efficient and high-quality color coating for various metal strips, including cold-rolled steel, galvanized plates, and aluminum coils. Engineered by a professional team with industry expertise, the system is tailored to meet customer needs with robust quality checks and reliable transportation standards.

Product Advantages

**Product Features**

Application Scenarios

- Double-coating and double-baking model with hot air circulation heating technology.

- Compatible materials include electro-galvanized, hot-dip galvanized, Al-Zn plates, cold-rolled steel, and aluminum coils.

- Supports strip thickness ranging from 0.12 to 1.8 mm and strip width from 600 to 1650 mm.

- Production speed varies from 30 to 200 meters per minute, with capacity between 30,000 and 300,000 tonnes annually.

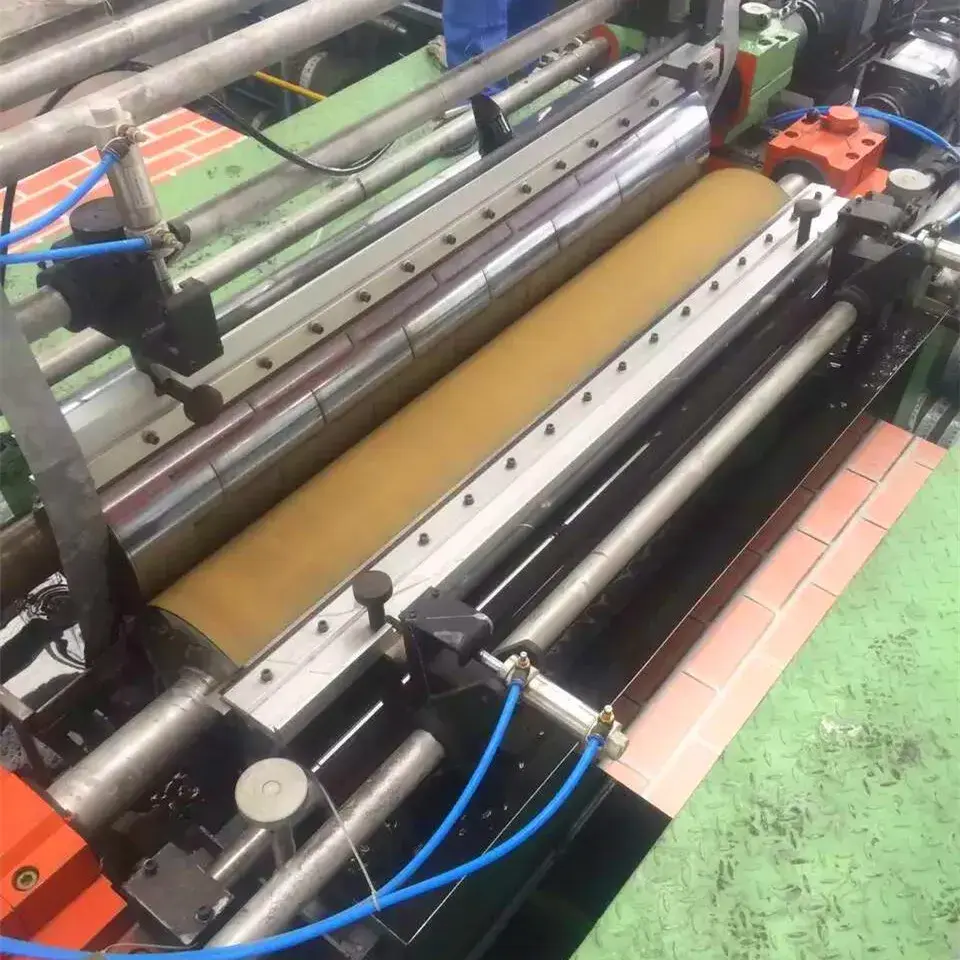

- Optional pattern printing system for decorative patterns such as mood grain, marble, and brick designs.

- English language software and HMI interface with customizable configurations.

**Product Value**

This coating line offers a tailor-made, competitive, and cutting-edge technological solution to enhance production efficiency, product quality, and customization. It brings strong value through innovation, reliable support, and the ability to meet diverse production goals and budget requirements, ensuring a solid return on investment for manufacturers.

**Product Advantages**

- State-of-the-art technology combined with competitive pricing and expert ongoing support.

- Flexible material compatibility and customizable configurations to adapt to various customer specifications.

- High precision in thickness control with tight allowable deviations for superior coating quality.

- Comprehensive service package including project feasibility, equipment design, installation, commissioning, technology transfer, operator training, and ongoing technical support.

- Capability to produce patterned coatings, enhancing product diversity and market competitiveness.

**Application Scenarios**

Ideal for metal manufacturing industries requiring high-quality coated steel or aluminum products, such as construction materials, automotive components, appliances, and decorative metal panels. It is suitable for large-scale production facilities seeking efficient, reliable, and customizable color coating solutions with potential for patterned finishes.