Product Overview

Certainly! Here's a summary of the "New Coil Processing Line Company" product based on the detailed introduction:

Product Features

**Product Overview**

Product Value

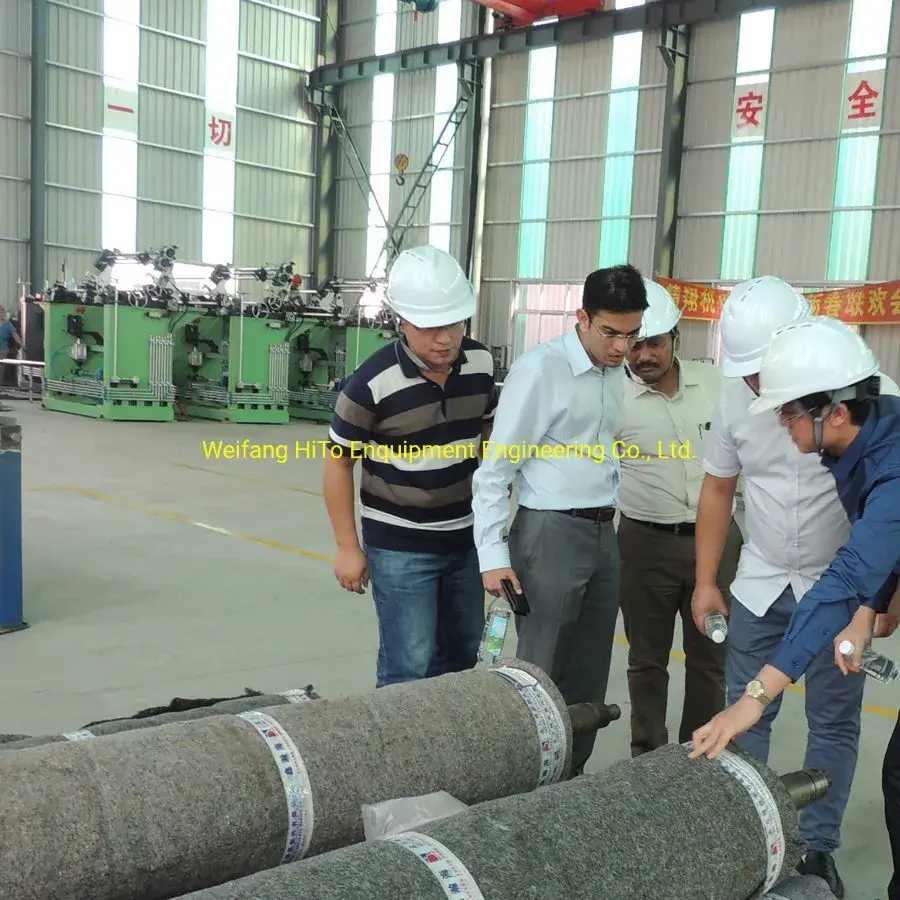

HiTo Engineering’s coil processing line is a high-quality, industry-leading metal strip processing system designed and manufactured by experienced professionals. It supports a variety of raw materials such as electro-galvanized plates, hot-dip galvanized plates, aluminum coils, and cold-rolled steel strips. The system features a color coating unit with double-coating and double-baking technology, enabling efficient and precise coating processes.

Product Advantages

**Product Features**

Application Scenarios

- Double-coating and double-baking model with hot air circulation heating for superior color coating.

- Supports strip thickness from 0.12 to 1.8 mm and width from 600 to 1650 mm.

- Process speed ranges from 30 to 200 meters per minute.

- Adjustable coating thickness on both front (5-25μm) and back (5-15μm) surfaces.

- Uses various energy sources like electricity, natural gas, and liquefied petroleum gas.

- Comes with pattern printing capabilities for unique surface designs such as mood grain or marble effects.

**Product Value**

The coil processing line greatly enhances production efficiency and quality control, with a capacity range of 30,000 to 300,000 tonnes per year. Its advanced technology and precision parameters improve product durability and aesthetic appeal. The company also offers comprehensive services including project feasibility, design, installation, commissioning, operator training, product testing, and ongoing technical support to maximize customer success.

**Product Advantages**

- Manufactured by a highly skilled engineering team ensuring minimal malfunctions and superior quality.

- Equipped with internationally recognized software and HMI interfaces in English for ease of operation.

- Customizable configurations according to customer requirements.

- Proven track record with flagship projects such as the DUBAI Industry City color coating line.

- Strong R&D and continuous improvement driven by a professional, multinational team supporting global markets including Southeast Asia, Middle East, and Africa.

**Application Scenarios**

Ideal for industries requiring precision-coated steel and aluminum strips such as construction materials, automotive panels, appliances, decorative metals, and other metal fabrication sectors. Suitable for large-scale production plants that require high throughput, consistent quality, and advanced coating techniques with pattern printing options.

---

If you need a more concise or technical summary, feel free to ask!