Product Overview

Here is a summary of the Steel Painting Line by HiTo Engineering based on the detailed introduction:

Product Features

**Product Overview**

Product Value

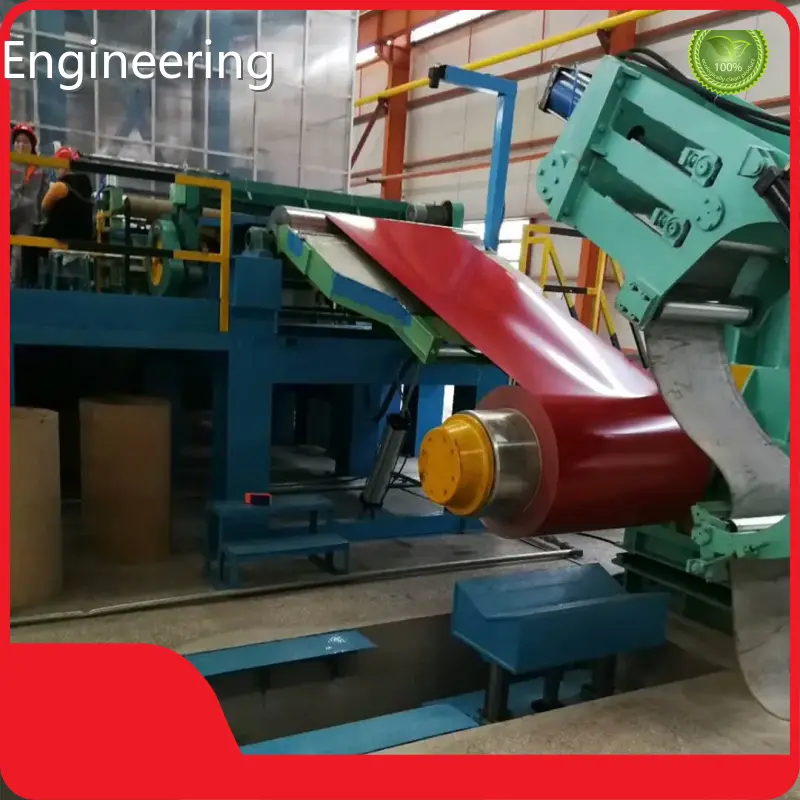

The Steel Painting Line by HiTo Engineering is an advanced color coating production system designed for processing various steel and aluminum strips with thicknesses ranging from 0.12 to 1.8 mm and widths from 600 to 1650 mm. It features a double-coating, double-baking model with hot air circulation heating, capable of producing high-quality coated steel sheets at speeds of 30 to 200 meters per minute and annual capacities between 30,000 to 300,000 tonnes.

Product Advantages

**Product Features**

Application Scenarios

- Utilizes the double-coating and double-baking process for superior coating quality.

- Supports multiple raw materials including cold rolled steel, electro-galvanized, hot-dip galvanized, Al-Zn coated plates, and aluminum coils.

- Equipped with a pattern printing system to produce decorative finishes such as mood grain, marble, and brick patterns.

- Offers flexible configuration options and English-language software and HMI interface for global usability.

- Incorporates precise thickness control with allowable deviations depending on precision grades, ensuring consistent product quality.

**Product Value**

The steel painting line provides a long life cycle and high durability for coated products, enabling prolonged storage and reliable performance. Its tailor-made solutions and competitive pricing give customers a strong competitive edge in the market. Additionally, the system ensures cost efficiency through advanced technology and fast production speeds, supporting high-volume output with excellent surface quality.

**Product Advantages**

- Manufactured with advanced, efficient equipment guaranteeing reliability and longevity.

- Backed by HiTo Engineering’s comprehensive service including project feasibility, design, installation, commissioning, training, and continuous technical support.

- Unique design and modular product lines allow adaptation to specific customer needs and production goals.

- Fast delivery coupled with specialist support ensures quick setup and operational readiness.

- Integration capabilities with downstream equipment streamline the entire production process for better productivity.

**Application Scenarios**

Ideal for large-scale industrial manufacturers requiring high-quality color coated steel or aluminum sheets, including automotive parts, construction materials, appliance manufacturing, decorative sheets, and pattern-coated steel products. The line suits operations demanding customizable coatings and patterns, high throughput, and consistent precision in thickness and surface finish.