Coil Coating Equipment Product Line Wholesale - HiTo Engineering

Product details of the coil coating equipment

Product Specification

Delivery Time: 3-5 Months

Condition: New

Origin: China

Coating: Coil Coating

Specification: 1600CBM

Quick Detail

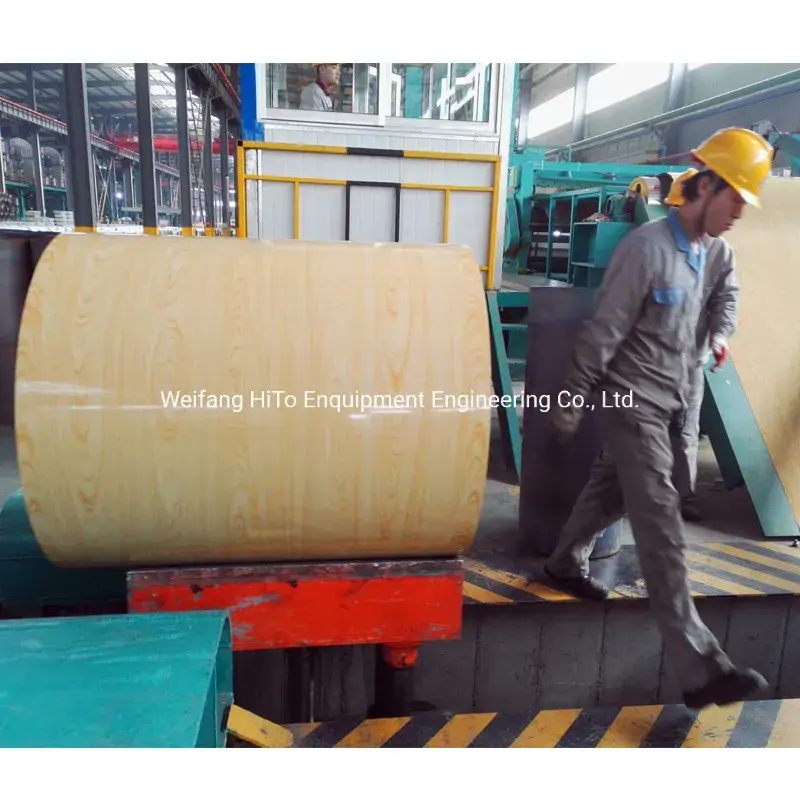

HiTo Engineering coil coating equipment has attracting designs with consistency. This product must go through our quality inspector's internal quality assurance procedure to ensure non-defective quality. Impeccable design, exquisite craftsmanship, and world-class collaborations are the foundations on which Weifang HiTo Equipment Engineering Co.,Ltd has been built.

Product Information

Supported by advanced technology, HiTo Engineering has a great breakthrough in the comprehensive competitiveness of coil coating equipment, as shown in the following aspects.

Product Description

- Material of base plate: electro-galvanized plate, hot-dip galvanized plate, hot dip Al-Zn plate, cold-rolled steel plate , Aluminum Coils etc.

- Raw material:cold rolled strip,GI,GL,aluminum strip

- Thickness of strip steel: 0.12-1.8mm, Width of strip steel: 600-1650mm

- Outer diameter of steel coil: φ800-2000mm

- Process speed: 30 - 200m/min

- Coating thickness : 5-25μm for the single-layer dry film on the front face (regulated as required) 5-15μm for the single-layer dry film on the back face (regulated as required)

- Production capacity: 30,000-300,000 Tonnes/year

- Energy type: electricity, natural gas, liquefied petroleum gas, etc.

| Nominal Thickness | Allowable Deviation of Thickness in Case of the Following Thicknesses | |||

| General Precision PT.A | High Precision PT.B | |||

| ≤1200 | >1200-1500 | ≤1200 | >120-1500 | |

| 0.20-0.40 | ±0.05 | ±0.06 | ±0.03 | ±0.04 |

| >0.40-0.60 | ±0.06 | ±0.07 | ±0.04 | ±0.05 |

| >0.60-1.0 | ±0.07 | ±0.08 | ±0.05 | ±0.06 |

Company Information

Weifang HiTo Equipment Engineering Co.,Ltd provides high-quality coil coating equipment with stable performance. HiTo Engineering wins a good reputation by its dedication to the coil coating equipment industry. Since its inception, HiTo Engineering has focused on market demand and continuously upgraded and improved its products. Call now!

Welcome to discuss business cooperation with us!