Revolutionizing Steel Production: The Innovations Of A Coil Galvanizing Line

Welcome to a groundbreaking article that dives deep into the world of steel production, exploring the cutting-edge innovations of a coil galvanizing line. This revolutionary technology is transforming the way steel is produced, creating stronger, more durable materials with a minimal environmental footprint. Join us on a journey through the fascinating advancements that are revolutionizing the steel industry and shaping the future of construction, manufacturing, and beyond.

- Introduction to Coil Galvanizing Lines in Steel Production

to Coil Galvanizing Lines in Steel Production

Steel production has undergone a revolution with the introduction of coil galvanizing lines. These innovative systems have transformed the manufacturing process, providing increased efficiency, quality, and environmental sustainability. In this article, we will explore the key features and benefits of coil galvanizing lines in steel production.

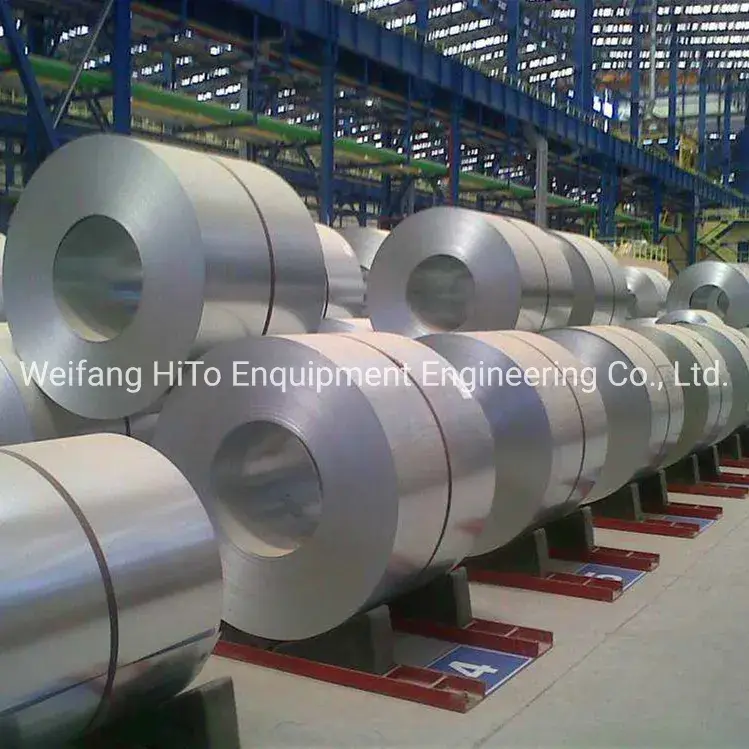

A coil galvanizing line is a crucial component in the production of high-quality, corrosion-resistant steel coils. These lines are designed to coat steel coils with a layer of zinc, which not only provides protection against rust and corrosion but also enhances the aesthetic appeal of the finished product. The process begins with the uncoiling of steel coils, which are then cleaned and pre-treated to ensure optimal adhesion of the zinc coating.

One of the key advantages of coil galvanizing lines is their ability to achieve consistent and uniform coating thicknesses. The automated nature of these systems ensures precise control over the application process, resulting in a high-quality finish that meets the strictest industry standards. This level of control also helps to minimize waste and reduce production costs, making coil galvanizing lines a cost-effective solution for steel manufacturers.

In addition to improving the quality of the end product, coil galvanizing lines also offer significant environmental benefits. By using a dry, chemical-free process, these systems eliminate the need for hazardous chemicals and reduce the overall environmental impact of steel production. Furthermore, the efficient use of resources and minimal waste generation make coil galvanizing lines a sustainable choice for manufacturers looking to reduce their carbon footprint.

Another key feature of coil galvanizing lines is their versatility. These systems are capable of processing a wide range of steel grades, sizes, and thicknesses, making them suitable for a variety of applications across industries. Whether producing automotive parts, building materials, or consumer goods, manufacturers can rely on coil galvanizing lines to deliver consistent results that meet their specific requirements.

Overall, coil galvanizing lines have revolutionized steel production by providing a cost-effective, environmentally friendly, and versatile solution for coating steel coils. With their ability to achieve uniform coating thicknesses, reduce waste, and enhance the durability of steel products, these innovative systems have become essential tools for modern manufacturers. As the demand for high-quality, corrosion-resistant steel continues to grow, coil galvanizing lines will play a pivotal role in meeting the needs of the industry and driving further advancements in steel production technology.

- Advancements in Technology for Efficient Steel Coating Processes

Steel production is undergoing a revolution with the advancements in technology for efficient steel coating processes, particularly with the innovations of a coil galvanizing line. This cutting-edge technology is transforming the way steel is coated with zinc, providing numerous benefits such as improved corrosion resistance, increased durability, and enhanced aesthetic appeal.

A coil galvanizing line is a specialized production line that applies a protective zinc coating to steel coils, ensuring they are corrosion-resistant and long-lasting. This process involves cleaning the steel coils to remove any impurities, followed by a series of coating and curing stages to ensure the zinc adheres firmly to the steel surface. The result is a high-quality product that is perfect for a wide range of applications, from construction materials to automotive components.

One of the key advantages of a coil galvanizing line is its efficiency. With the use of automated systems and advanced technology, the coating process can be completed quickly and accurately, reducing production time and costs. This efficiency also extends to the environmental impact of the process, as less waste is generated and energy consumption is minimized.

In addition to efficiency, a coil galvanizing line also offers versatility in terms of the types of coatings that can be applied. Zinc is the most common coating used in galvanizing lines, but other coatings such as aluminum or zinc-aluminum alloy can also be applied, depending on the requirements of the end product. This flexibility allows manufacturers to meet the specific needs of their customers and produce high-quality coated steel that meets industry standards.

Furthermore, the innovations of a coil galvanizing line have led to improvements in the quality of the coated steel produced. The precise control of coating thickness and uniformity ensures a consistent product that meets the highest standards of performance and durability. This is particularly important in industries where the integrity of the steel is crucial, such as in construction or infrastructure projects.

Overall, the advancements in technology for efficient steel coating processes, specifically with the innovations of a coil galvanizing line, are revolutionizing the way steel is produced. The efficiency, versatility, and quality of the coating process are driving improvements in the performance and durability of coated steel products, making them an essential component in a wide range of industries. As technology continues to evolve, the future of steel production looks brighter than ever before.

- Benefits of Implementing a Coil Galvanizing Line in Steel Manufacturing

Steel manufacturing has been revolutionized by the implementation of coil galvanizing lines in production processes. These innovative lines offer a multitude of benefits that improve efficiency, reduce costs, and enhance the quality of the final product. In this article, we will explore the various advantages of utilizing a coil galvanizing line in steel manufacturing.

One of the key benefits of a coil galvanizing line is its ability to enhance the corrosion resistance of steel products. Galvanizing involves coating steel with a layer of zinc, which acts as a protective barrier against rust and corrosion. By incorporating a galvanizing line into the production process, manufacturers can ensure that their steel products have a longer lifespan and require less maintenance over time.

In addition to improving corrosion resistance, coil galvanizing lines also help to enhance the aesthetic appeal of steel products. The zinc coating provides a shiny, metallic finish that is visually appealing and can help products stand out in the market. This can be particularly beneficial for industries that require attractive, high-quality steel products, such as construction or automotive.

Furthermore, coil galvanizing lines offer increased efficiency and productivity in steel manufacturing. The automated nature of these lines allows for faster processing times and higher output levels, leading to greater productivity and lower manufacturing costs. Additionally, the consistent application of the zinc coating ensures that each product meets strict quality standards, reducing the likelihood of defects or rework.

Another advantage of implementing a coil galvanizing line is the environmental benefits it provides. By using zinc as a coating material, manufacturers can reduce their reliance on toxic chemicals and harmful substances, leading to a more environmentally friendly production process. Additionally, the longevity of galvanized steel products means that they require less frequent replacement, resulting in less waste and a smaller carbon footprint.

Overall, the innovations of a coil galvanizing line have had a significant impact on the steel manufacturing industry. From improving corrosion resistance and aesthetic appeal to enhancing efficiency and reducing environmental impact, the benefits of implementing a galvanizing line are clear. As technology continues to advance, it is likely that these lines will become even more integral to the steel production process, leading to further improvements in quality and sustainability.

- Sustainability and Environmental Impact of Modern Steel Production Methods

Steel production has been a vital industry for centuries, providing the backbone for infrastructural development and economic growth around the world. However, traditional steel production methods have come under increasing scrutiny for their negative environmental impact and unsustainable practices. In response to these challenges, the steel industry has been revolutionized by the introduction of modern coil galvanizing lines, which have transformed the way steel is produced, improving its sustainability and reducing its environmental footprint.

A coil galvanizing line is a state-of-the-art facility that applies a protective zinc coating to steel coils, enhancing their durability and corrosion resistance. This process not only improves the quality of the steel but also reduces the need for maintenance and repairs, prolonging its lifespan and reducing waste. In addition, the zinc coating can be recycled and reused, further minimizing its environmental impact.

One of the key advantages of coil galvanizing lines is their efficiency and precision. By automating the galvanizing process, these advanced facilities can produce high-quality coated steel at a faster rate and with greater consistency than traditional methods. This not only increases productivity but also reduces energy consumption and waste, making the production process more sustainable and cost-effective.

Furthermore, coil galvanizing lines are equipped with advanced monitoring and control systems that optimize the use of resources and minimize emissions. By carefully managing temperature, pressure, and chemical inputs, these facilities can achieve superior coating quality while minimizing the release of harmful pollutants into the environment. This not only improves air and water quality but also ensures compliance with stringent environmental regulations.

Another significant benefit of coil galvanizing lines is their ability to produce a wide range of coated steel products for various applications. From construction materials to automotive components, these facilities can customize the thickness, coating type, and surface finish of the steel coils to meet the specific requirements of different industries. This versatility not only expands the market for coated steel products but also reduces the need for multiple production lines, streamlining the manufacturing process and conserving resources.

In conclusion, the innovations of coil galvanizing lines have revolutionized the steel production industry, improving its sustainability and reducing its environmental impact. By integrating advanced technologies and optimized processes, these facilities have transformed the way steel is coated, enhancing its quality, durability, and recyclability. As the demand for sustainable materials continues to grow, coil galvanizing lines are poised to play a key role in shaping the future of steel production and driving the transition towards a more eco-friendly and resource-efficient economy.

- Future Implications and Further Innovations in Coil Galvanizing Lines

Revolutionizing Steel Production: The Innovations of a Coil Galvanizing Line - Future Implications and Further Innovations in Coil Galvanizing Lines

Steel production has long been a vital industry, providing the backbone for construction, manufacturing, and infrastructure projects around the world. In recent years, advancements in technology have led to significant innovations in the way steel is produced, with coil galvanizing lines at the forefront of these developments. These lines have revolutionized the galvanizing process, making it more efficient, cost-effective, and environmentally friendly.

One of the key innovations in coil galvanizing lines is the introduction of automated systems. These systems allow for precise control over the galvanizing process, ensuring consistent coating thickness and quality across each coil. By reducing human error and minimizing waste, these automated systems have helped to improve the overall efficiency of galvanizing lines, resulting in higher output and lower production costs.

In addition to automation, advancements in materials science have also played a crucial role in the evolution of coil galvanizing lines. New coatings and alloys have been developed that provide enhanced corrosion resistance and durability, making galvanized steel an even more attractive option for a wide range of applications. These innovations have opened up new markets for galvanized steel, driving demand and creating opportunities for further growth in the industry.

Looking towards the future, there are a number of exciting developments on the horizon for coil galvanizing lines. One area of focus is on sustainability, with manufacturers seeking to reduce their environmental impact through the use of recycled materials and energy-efficient processes. By adopting more sustainable practices, coil galvanizing lines can not only minimize their carbon footprint but also appeal to eco-conscious consumers who are increasingly demanding greener products.

Another area of innovation is in the realm of digitalization and data analytics. By harnessing the power of big data, manufacturers can gain valuable insights into their production processes, identifying areas for improvement and optimizing efficiency. This data-driven approach can lead to faster turnaround times, reduced downtime, and lower operating costs, ultimately increasing the competitiveness of coil galvanizing lines in the global market.

Overall, the advancements in coil galvanizing lines have had a profound impact on the steel industry, driving efficiency, quality, and sustainability. As we look towards the future, it is clear that further innovations in this field will continue to shape the way steel is produced, with exciting new possibilities on the horizon. By embracing automation, materials science, and digitalization, manufacturers can stay ahead of the curve and revolutionize steel production for years to come.

Conclusion

In conclusion, the implementation of a coil galvanizing line has truly revolutionized steel production in countless ways. From improving the quality and durability of steel products to enhancing efficiency and reducing environmental impact, the innovations brought forth by this technology have truly changed the game for manufacturers in the industry. As we continue to push the boundaries of what is possible in steel production, it is evident that the coil galvanizing line will remain a vital tool in the quest for progress and innovation. The future of steel production is brighter than ever, thanks to the groundbreaking advancements made possible by this game-changing technology.