Product Overview

Certainly! Here's a summary of the HiTo Engineering Color Coating Line Process Wholesaler based on the detailed product introduction:

Product Features

**Product Overview**

Product Value

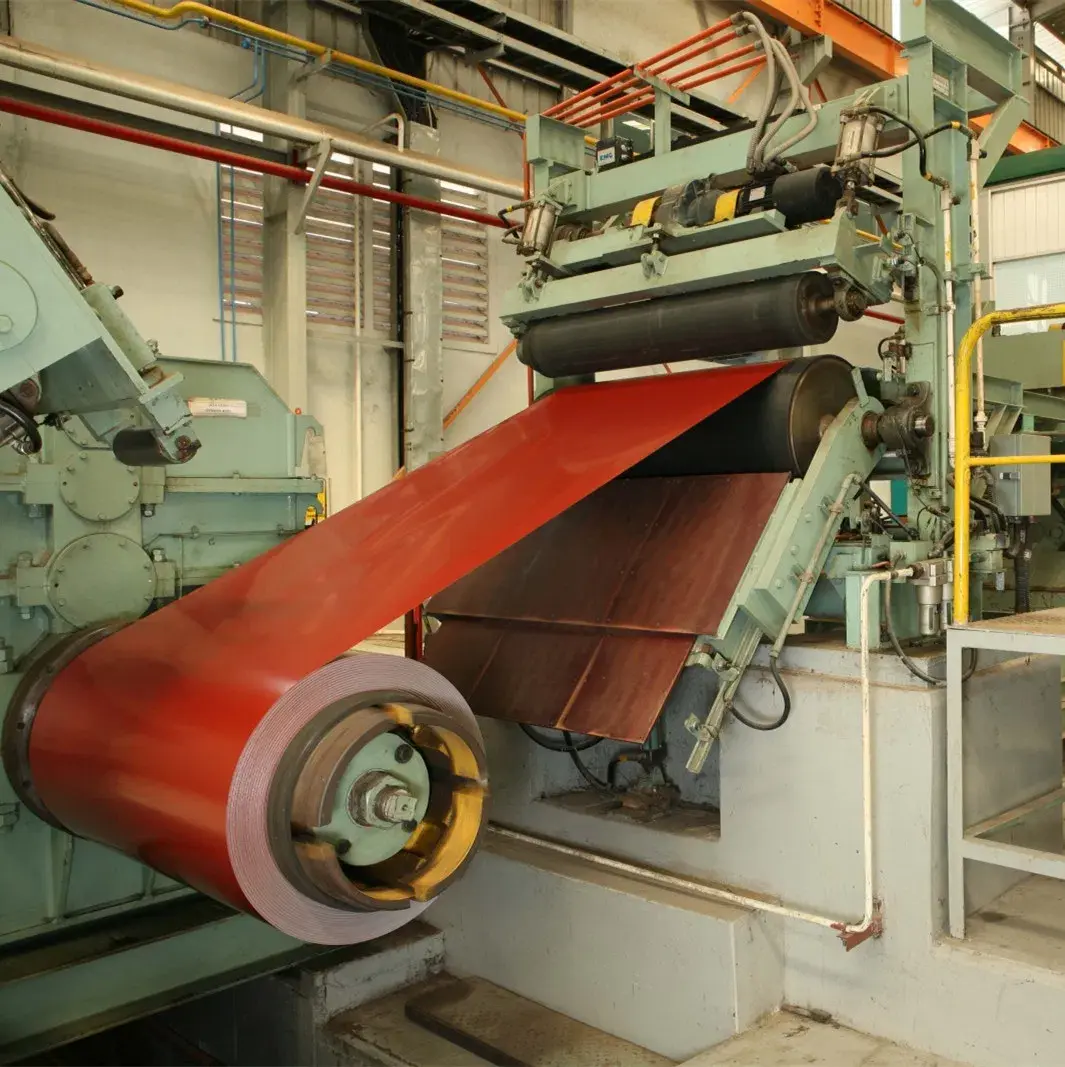

HiTo Engineering’s color coating line process is a technologically advanced coating production line originating from China, designed for coating aluminum and steel substrates. It incorporates international advanced technology to ensure smooth, efficient, and precise coating operations suitable for large-scale industrial production.

Product Advantages

**Product Features**

Application Scenarios

- Uses a double-coating, double-baking model combined with hot air circulation heating.

- Compatible with various base materials like electro-galvanized plates, hot-dip galvanized plates, hot dip Al-Zn plates, cold-rolled steel plates, and aluminum coils.

- Processes cold-rolled strips, GI, GL, and aluminum strips with thicknesses of 0.12-1.8mm and widths of 600-1650mm.

- Operates at speeds from 30 to 200 meters per minute, and production capacity ranges from 30,000 to 300,000 tonnes per year.

- Includes an optional pattern printing system for decorative coatings (e.g., wood grain, marble, brick patterns).

**Product Value**

HiTo Engineering provides tailor-made solutions that align with customer requirements, production goals, and budget constraints. The line offers a competitive advantage by combining world-class technology with cost-effective pricing and extensive post-sale support, enabling businesses to improve product quality and production efficiency.

**Product Advantages**

- High precision in thickness control with strict allowable deviations for general and high precision level products.

- The software interfaces and HMI are fully in English, ensuring ease of use internationally.

- Flexibility in configuration allows customers to customize the line according to their needs.

- Comprehensive support services, including project feasibility studies, equipment design, installation, commissioning, operator training, product testing, technology transfer, downstream equipment integration, and ongoing technical support.

**Application Scenarios**

Ideal for heavy industrial manufacturing plants producing coated steel and aluminum products for construction, automotive, appliance, packaging, and decorative industries. Suitable for enterprises requiring large volume production with consistent quality and decorative pattern coating options.

If you need further refinement or additional details, feel free to ask!